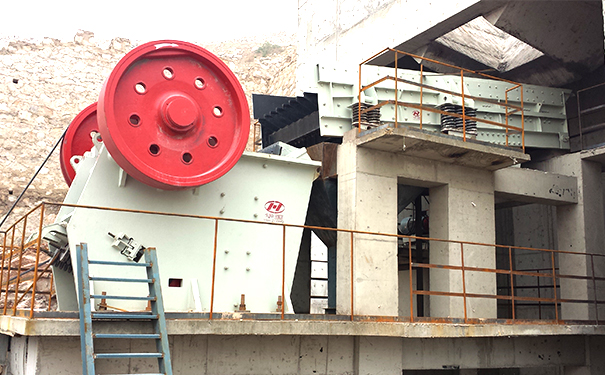

Jaw crusher has many advantages, which is recognized and loved by different users. In terms of crushing, jaw crusher can be adjusted according to the different needs of users on the size of the discharge particle size. However, there are also users who report that there will be uneven discharging particle size in the process of use. What causes the uneven discharging particle size? How to adjust it? Luoyang Dahua believes that this phenomenon is caused by non-standard operation or machine failure in the production process, followings are the causes and measures.

1. Abrasion of broken parts

Due to the harsh working environment and the high hardness of the broken materials, the broken parts will have certain wear in the crushing process. After wear, the clearance between the moving jaw and the bearing becomes larger, and the bearing will rotate relatively, which not only affects the crushing efficiency, but also leads to the uneven particle size of the material. Therefore, when the jaw crusher works for a period of time, regular maintenance should be carried out. If the broken parts are found to be worn, the moving jaw and bearing should be replaced immediately, so that the crushing particle size is uniform.

2. Movement of the jaw plate

In the crushing process, if it is found that the position of the jaw plate moves, the tooth root corresponding to the crown moves, and the crown is opposite to the crown, the particle size of the crushing will be different. Then the size of the tooth pitch of the tooth plate should be checked. If the size is not up to standard, the jaw plate must be replaced, and then the movable jaw plate and the fixed jaw plate should be adjusted to ensure that the top of the tooth is aligned with the root. After adjusting all the positions, it is fixed and pressed, so that the position no longer moves.

3. Lack of motivation

Power keeps the machine running, insufficient power of jaw crusher may affect the normal operation of the machine, resulting in low discharge particle size, and uneven discharge particle size. When the power of the jaw crusher is insufficient, the voltage at work should be raised, so that the host can run normally at work.

4. Size of the discharge opening

According to the size of the discharge particle size, the discharge opening of the jaw crusher is adjusted in time.

If you want to know more of Luoyang Dahua crushing equipment, sand making equipment, milling equipment please focus on the web site: https://www.lydhchina.com Whatsapp: +86 13938852499.