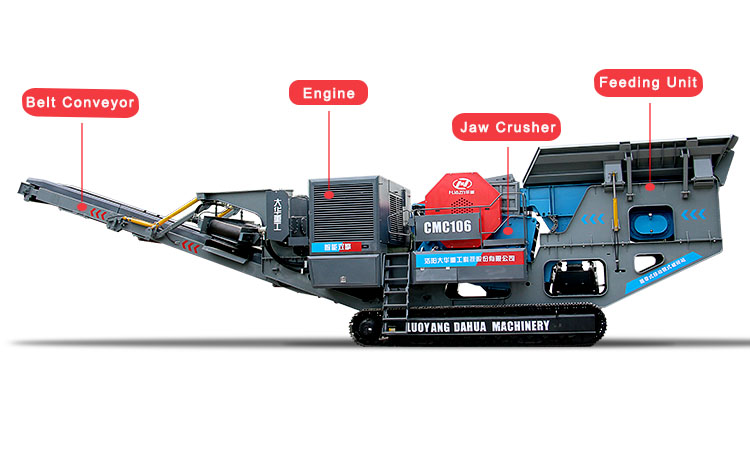

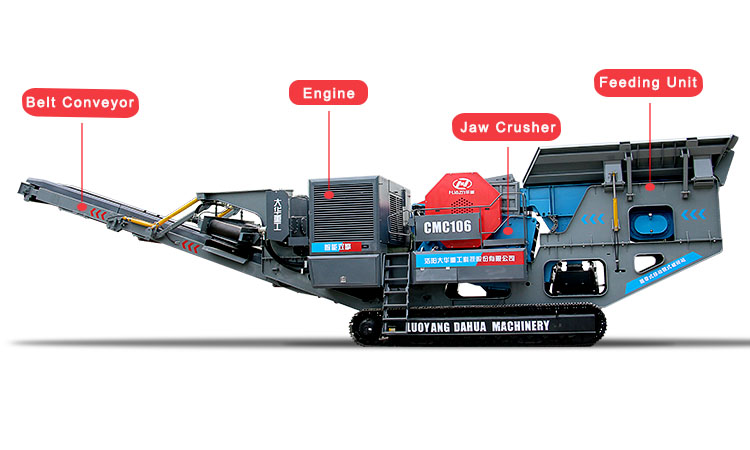

The mobile crushing plant capacity is between 100 and 500 tons per hour. It is used to crush rocks and other hard materials. The mobile crushing plant typically includes feeding unit, crushing unit, screening unit, and conveying unit. What is the function of these four units?

Four structures of mobile crushing plant

1. Feeding unit: The function of the crawler type mobile crushing plant feeding unit is to supply raw materials to each section of the crusher and screen. Depending on the specific crushing and screening process, different feeding methods are employed. Generally, vibrating feeders are widely utilized in production.

2. Crushing unit: The crushing unit is the heart of the entire equipment, responsible for crushing raw materials into small particles that can be used as finished products. Commonly used crushers include jaw crushers, impact crushers, and cone crushers.

3. Screening unit: The small crushed ore particles must be screened by screening machine before they can be used as a finished product. Additionally, the screening machine also serves to pre-screen.

4. Conveying unit: The crawler type mobile crushing plant conveying unit is primarily used for transferring ore between various levels of gravel screening equipment. Additionally, it facilitates the closed cycle by enabling the return of gravel. Moreover, it efficiently transports finished materials to different locations for stacking, with belt conveyors being widely utilized in production.

Crawler type mobile crushing plant features

1. The crawler mobile crushing plant is lightweight and compact, making it particularly suitable for narrow site work.

2. The transportation is convenient, with track walking that causes no damage to the road surface and has a wide range of adaptation.

3. The crawler type mobile crushing plant integrates the process equipment for material reception, crushing, and conveying. By optimizing the process flow, it achieves excellent performance in rock crushing, aggregate production, and open-pit mining. It can create a powerful line of crushing operations by combining different models to fulfill various processing needs.

4. The entire machine is equipped with all-wheel drive, allowing for on-site steering. It comes with standard configuration and a quick change device, along with perfect safety protection functions. This makes it particularly suitable for narrow and complex areas.

5. The fuel saving rate can reach up to 25%.

6. Improved design of a versatile power group with the ability to climb and meet the crushing demands of various projects, including mines, hydropower stations, and coal mines.

Crawler type mobile crushing plant applicable raw materials: limestone, calcite, granite, basalt, river pebbles, slag, slag stone, marble, gypsum and other types of mining, rock, construction waste. Application: Used in urban construction waste treatment, building materials, cement, chemical, mining and other industries.