The selection of equipment for stone production line has a significant impact on meeting the requirements of construction sites, stone grading, needle content, and other factors.

The compressive strength ratio of concrete coarse aggregate to the concrete strength grade should not be less than 1.5. It is commonly used for producing concrete coarse aggregates with rock compressive strengths ranging from S0 to 300MPa. The secondary crushing process is commonly utilized in stone production lines when the compressive strength of the rock exceeds 150MPa. The main equipment generally used in the secondary crushing process is: vibration feeder – primary crushing (generally jaw crusher) – secondary crushing (can be the impact crusher, cone crusher, or vertical shaft impact crusher) – vibrating screen – finished stone, and the material is transferred by belt conveyor.

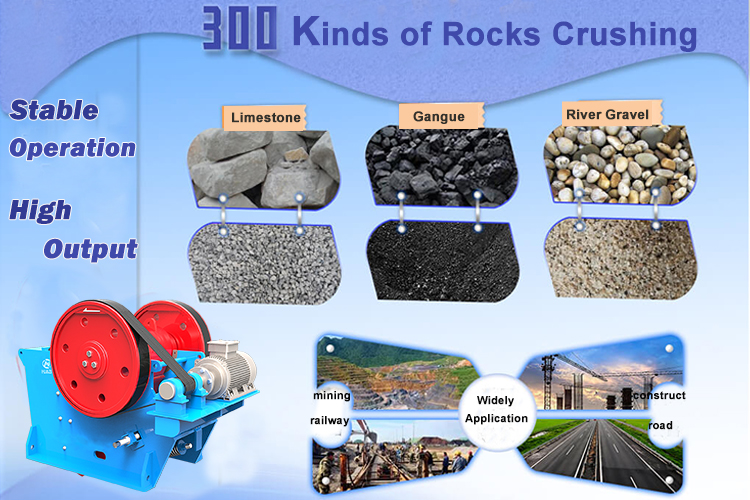

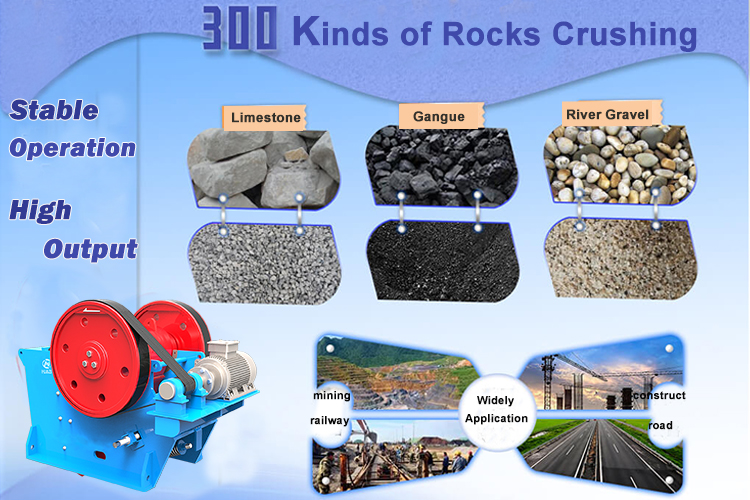

1, Primary crushing machinery

★ Jaw crusher is commonly applied, which employs the extrusion and bending action of two jaw plates to break materials of varying hardness.

Advantages: Simple structure, reliable operation, lightweight design, affordable price, compact size, low configuration height, large feed opening, easy adjustment of the discharge opening, effortless maintenance and economical operating costs.

Disadvantages: The liner’s susceptibility to wear, a high content of needle flakes in the product, and the need for specialized feeding equipment.

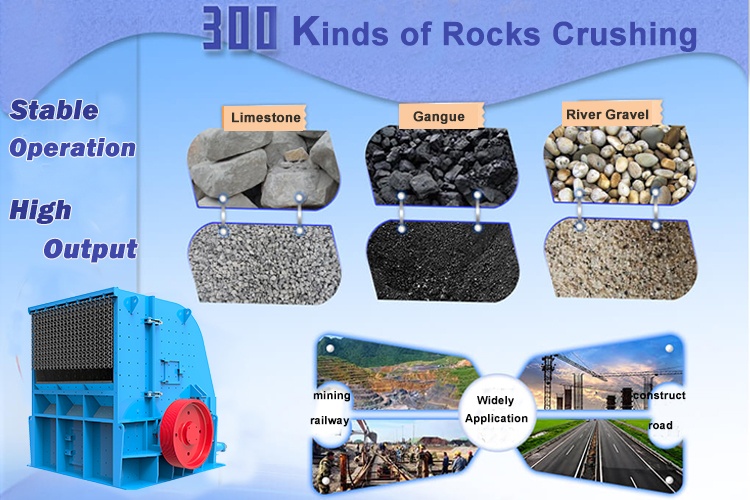

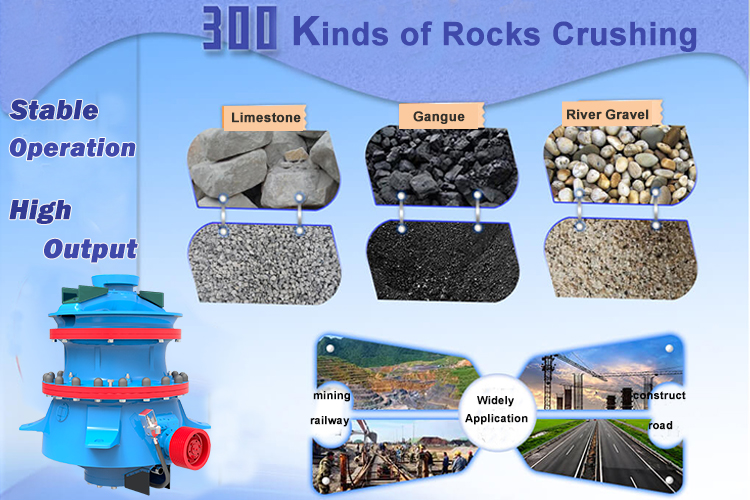

2, Secondary crushing machinery

Commonly used impact crusher, cone crusher or vertical shaft impact crusher.

★ Impact crusher is a crushing machine that utilizes the energy of impacts to fracture materials. By adjusting the gap between the impact frame and the rotor, impact crusher is possible to modify both the particle size and shape of the material.

Advantages: Small size, simple structure, large crushing ratio (up to 40), large production capacity, uniform product particle size, selective gravel action, and high output.

Disadvantages: The structure and maintenance of the system are characterized by a higher degree of complexity, while the physical dimensions are larger and the cost is relatively high.

★ Cone crusher utilizes the crushing action of the gyrating cone within the inner chamber of the cone shell to exert a compressive force on materials, causing them to undergo splitting and bending forces that facilitate their fragmentation into smaller sizes. This cone crusher machine is exclusively designed for either primary or secondary crushing operations.

Advantages: The crushing ratio is large, the efficiency is high, the energy consumption is low, there is less dust, the product particle size is uniform, the work is stable, and the failure rate is low.

Disadvantages: The structure and maintenance are more complex, the body is high, and the price is expensive.

★ Vertical shaft impact crusher, commonly known as the sand making machine, operates by allowing stones to naturally fall and then accelerating their collision through an impeller in order to achieve crushing. When the stone propelled by acceleration collides with the naturally falling stone, a vortex is generated and subsequently disrupted twice during its return trajectory.

Advantages: The equipment features low energy consumption, high output, a large crushing ratio, compact size, easy operation and maintenance, as well as shaping capabilities that produce cubic products with high bulk density.

Disadvantages: Due to the complexity of maintenance and high cost, the maximum feed size for general use should not exceed 60mm. This makes it suitable for fine crushing and sand making applications.

The proper selection of stone production line equipment not only ensures the fulfillment of actual production requirements, but also satisfies the demands for particle size grading and needle sheet content of aggregate. As a result, it enhances production efficiency and reduces construction costs, which holds significant importance for on-site production and construction.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher. From machine selection to site installation, and operator training, the professional engineer will take in charge of the whole process. Please contact us at any time to get latest quotation.