As a substitute for natural sand, machine-made sand effectively fills the vacancy in the market demand for sand and gravel. With the development of infrastructure industry and increasing emphasis on construction project quality, there is a growing need for higher-quality sand. The quality of mechanical sand directly impacts concrete quality, making it crucial to enhance the quality of machine-made sand.

High-quality machine-made sand can meet the needs of different construction projects, so how to produce high-quality machine-made sand?

1. Sand making raw materials

The quality of processed machine sand is highly dependent on the used raw materials. Some raw materials contain impurities such as dirt and dust, which can negatively impact the cleanliness and overall quality of the machine sand. Not all materials are suitable for the production of machine-made sand. In order to ensure the strength and durability of machine-made sand, it is necessary to select raw materials with appropriate lithology, such as granite and limestone, which possess high compressive strength and suitable chemical composition.

2. Machine-made sand crushing equipment

The particle size and grading requirements of the material are the primary factors determining the quality of sand aggregate. By utilizing efficient crushing equipment, vibrating screens, and appropriately sized square hole screens, it is possible to effectively control the particle size of the sand. Therefore, selecting suitable crushing equipment is crucial.

3. Personnel factors

The professional expertise and competence of the operators themselves are crucial factors that impact the quality of sand and stone. The organizers and managers involved in the project also exert a certain level of influence on the project’s quality. Therefore, effective control over human factors is crucial to ensuring project quality.

4. Processing technology

The appropriate processing method should be chosen based on the different process characteristics and specific circumstances. For instance, In cold and arid areas in the north, dry sand is more used, while wet sand is more suitable for the south.

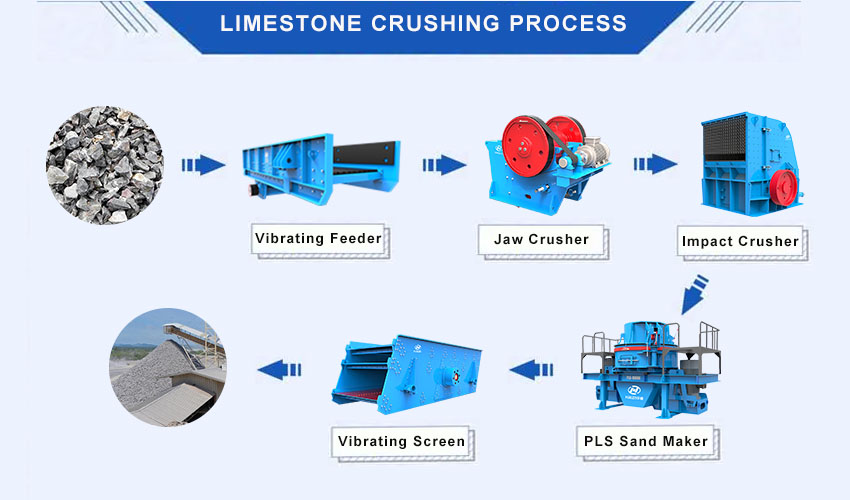

Machine sand production process: The basic production process can generally be divided into the following stages: coarse crushing → medium crushing → fine crushing (sand making) → screening → dust removal → machine sand.

A complete machine-made sand production line can be divided into three parts: crushing, sand making, and sand washing. The mechanical equipment involved in the processing of artificial sand includes a vibrating feeder, a jaw crusher, a cone crusher, an impact crusher, a vibrating screen, a vertical impact sand making machine, a sand washing machine, a belt conveyor, and centralized electronic control equipment, etc.