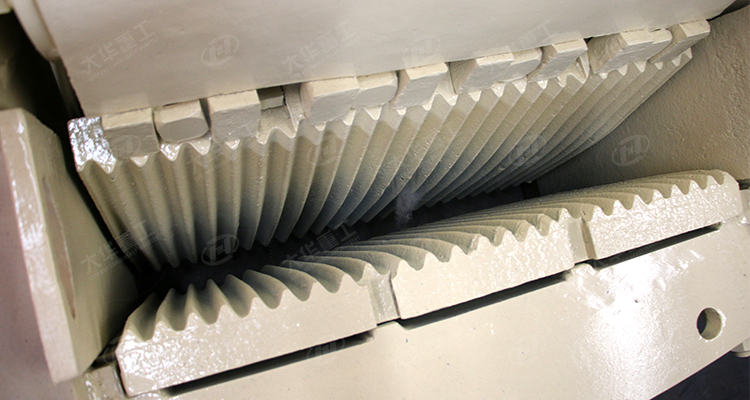

The jaw crusher operates on the principle of a movable jaw plate periodically moving back and forth against a fixed jaw plate, resulting in material being crushed through extrusion, splitting, and impact. Consequently, long-term crushing operations can lead to significant wear on the jaw plate as a wearing part. This wear not only directly affects the quality of crushing production but also poses safety risks to the crusher itself. How can we reduce this wear on the jaw plate?

1. Control the feeding size

The material fed into the jaw crusher should be within the specified size range, and caution should be exercised to prevent any iron or other impurities from entering the machine, in order to avoid excessive wear on the tooth plate.

2. Material selection of jaw plate

When purchasing a jaw crusher or replacing the jaw plate, it is essential to select a jaw plate made of materials with high hardness, strong toughness, and excellent wear resistance. Practical experience has demonstrated that the high manganese alloy jaw plate offers superior durability.

3. Timely repair of wear

The regular maintenance of the jaw crusher includes checking the usage of the jaw plate. If any worn-out jaw plate is found, it can be repaired through surfacing welding to prolong its service life.

4. Pay attention to fastening jaw plate

The most fundamental aspect of installation is to firmly fix the jaw plate. The jaw plate can be shaped like a tooth, and if necessary, a layer of plastic material can be placed between the jaw plate and the jaw head to ensure a secure fixation. This ensures stable contact between the jaw plate and the jaw crusher, reducing friction.

5. Prohibit long-term overload operation of equipment

The equipment will crack at the root of the tooth plate if it is overloaded for a prolonged period. These cracks will gradually expand, leading to the failure of the tooth plate. Therefore, when operating the jaw crusher, it is important to strike a balance between work and rest. Avoid solely focusing on output and overloading the jaw crusher for an extended duration as this can cause severe damage to its working parts, including the tooth plate.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.