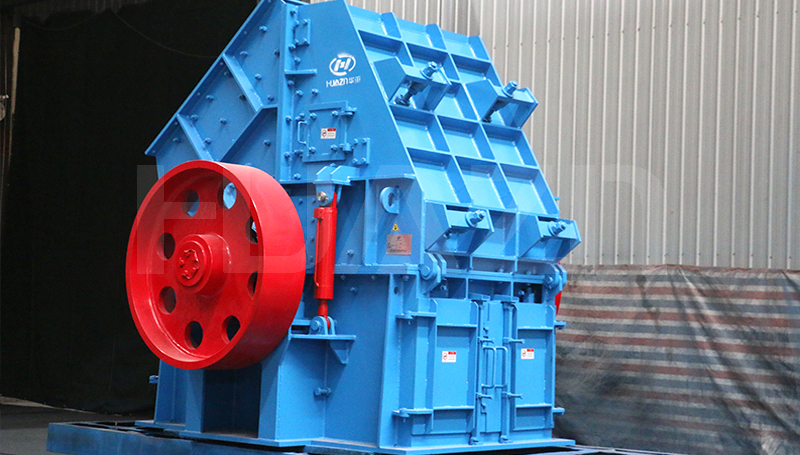

The hammer crusher is commonly used in the mining industry, and it is often employed to crush various ores and large pieces of material. However, due to the heavy workload and intense vibrations during operation, the hammer crusher has a variety of failures in the process that hinder its normal use. The serious bounce of the rack is one of the failures. So what is the reason for this phenomenon? How can we solve it?

When the hammer crusher is found to be severely bouncing, it should first be stopped for checking the following aspects.

1、Whether the anchor bolt is loose or broken.

2、Whether the foundation of the hammer crusher machine is stable, there are measures for vibration isolation or not.

3、Whether the position of the flying slot wheel runs off.

Solutions

1、If the hammer crusher is severely shaken due to the instability of the main machine, it is necessary to strengthen the foundation and add sleepers or rubber strips between the machine and the ground.

2、If the anchor bolt is loose, tighten it with a wrench. If the anchor bolt is broken, it needs to be replaced.

3、The solution to the deviation in flywheel position is to remove the cover plate of the flywheel, loosen the bolt that tightens the flywheel sleeve, adjust the position of the flywheel, and then tighten the bolt that secures the flywheel sleeve.

In summary, this is the reason for the serious bounce of the hammer crusher rack and its solution. We all know that the rack of the hammer crusher is mainly used to support the eccentric shaft and withstand the reaction force of the broken material, playing a crucial role in its operation. Therefore, any failure during equipment usage should be promptly identified and resolved to prevent a decrease in work efficiency.