The iron ore is a valuable mineral resource that finds extensive applications in metallurgy, construction, and the chemical industry. To optimize its usage, it is necessary to undergo crushing for subsequent processing. This paper aims to present the process flow of an iron ore crushing production line and its application.

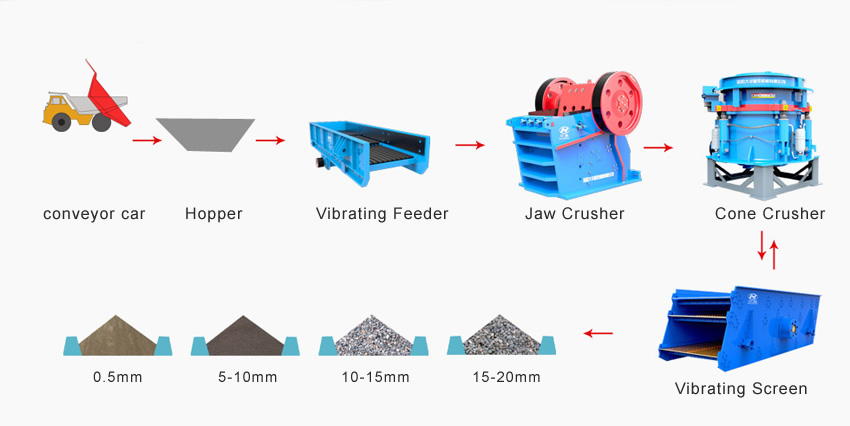

✦ Iron ore crushing production line process flow

Ore crushing is the first step in the iron ore processing procedure. The raw ore is crushed to achieve the necessary particle size, which provides suitable materials for subsequent beneficiation and refining processes. Commonly utilized crushing equipment includes jaw crusher, cone crusher, and impact crusher. A well-thought-out selection and configuration of crushing equipment can enhance both crushing efficiency and product quality.

1. Iron ore feed

The transport equipment carries iron ore to the feed hopper of the crushing line. To ensure a consistent feeding of ore, the feed hopper is typically equipped with a vibrating feeder. Vibrating feeders can evenly distribute iron ore for the next process.

2. Pre-screen

After being transported by the vibrating feeder, the iron ore in the hopper enters the pre-screening equipment. Typically, circular or linear vibrating screens are used for pre-screening to ensure that iron ore is screened within a specific size range. This process helps eliminate excessively large or small particles of iron ore, thereby reducing the burden on subsequent processes.

3. Crushing

The pre-screened iron ore is fed into the crushing plant for further processing. Common types of crushing equipment include jaw crushers, impact crushers, and cone crushers. These machines use mechanical force to crush, shock, or shear the iron ore, reducing it into smaller particles. The choice of crusher should be reasonably determined based on the hardness, humidity, and production requirements of the iron ore.

4. Screening

The crushed iron ore is screened using vibrating screening equipment, typically equipped with multi-layer screens that are categorized based on the particle size requirements of the iron ore. Once screened, the iron ore meeting the specifications proceeds to the next stage, while those failing to meet them are sent back for re-crushing.

5. Washing

The washing process is used to remove impurities from iron ore and enhance its grade. Commonly used washing equipment includes wet magnetic separators, heavy medium separators, and flotation machines. Different process methods are utilized for washing the iron ore based on its nature and requirements. After undergoing the washing process, the obtained iron ore exhibits high purity and grade, making it suitable for direct utilization in smelting or other purposes.

6. Finished iron ore transportation

After the processes of crushing, screening, and washing, the finished iron ore needs to be efficiently transported and stored using conveyor equipment. Commonly used conveying equipment includes belt conveyors, bucket elevators, and screw conveyors. These devices ensure a quick and smooth transportation of finished iron ore to designated storage areas, providing essential raw material support for subsequent production processes.

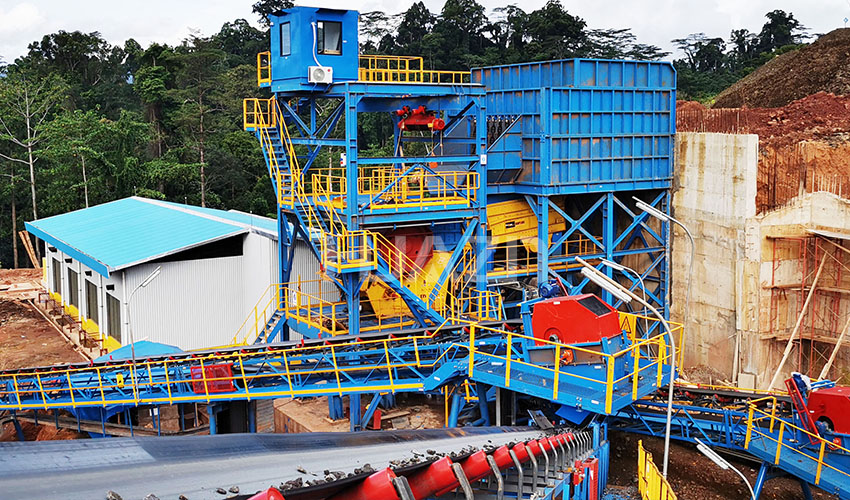

Customer Application

✦ 550t/h iron ore crushing production line

Material: iron ore

Production capacity: 550 t/h

Equipment: HZG vibrating feeder, ASD jaw crusher, cone crusher, 3YKR vibrating screen