The limestone impact crusher, also known as the impact crusher, can independently complete the limestone coarse or fine crushing. This impact crusher is mainly used in metallurgy, chemical industry, building materials, hydropower, highway, railway and other limestone crushing operation. It can be configured according to the type of limestone, scale and finished material requirements.

Why is impact crusher the main equipment for processing limestone? The largest application of limestone is in cement manufacturing. Impact crusher is the main equipment in the limestone processing, the discharging partial size can be adjusted for various purposes.

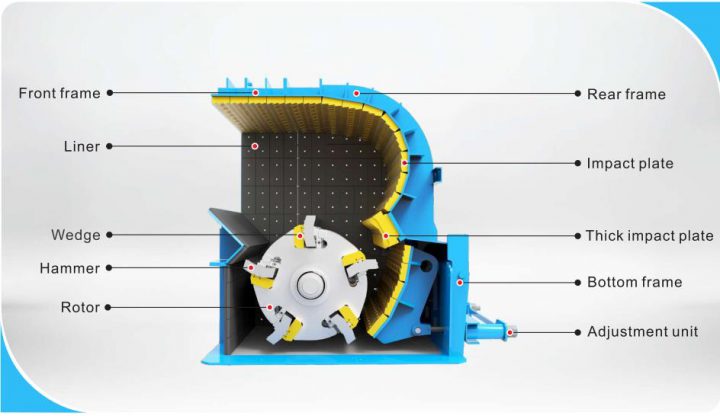

Crushing Principle – Limestone impact crusher uses impact energy to break limestone materials.

When the materials get into the action area of plate hammer, they are crushed by the hammer at a high speed. The crushed materials are thrown to the impact plate along the tangential direction to crush again. Then they are rebounded from the first impact plate to the action area of the plate hammer and enter into the second impact plate to repeat the above process. During this process, materials also crash with each other. This process will proceed repeatedly until the material are crushed to the required granularity, and then discharged from the clearance between impact plate and plate hammer.

Limestone impact crusher performance advantage

High safety performance

The impact plate adjustment system of the limestone impact crusher is also used as the overload protection device of the whole machine to prevent the damage to the equipment caused by broken limestone materials, foreign bodies or unbreakable objects. Low failure rate, and long maintenance cycle.

Strong flexibility

Limestone impact crusher is widely used, to achieve the integration of unit equipment installation form, more flexible adaptability.