What Factors should be Considered when Determine the Actual Rotation Speed of Ball Mill?

When determine the actual rotation speed of ball mill, we need to consider the following factors like mill diameter, production mode, liner plate shape and so on

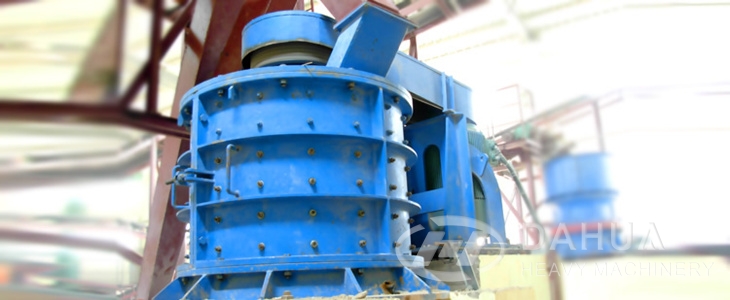

Four Methods to Prevent the Sand Making Machine Rusting

All iron products are capable of rusting, even the sand making machine is no exception In order to solve this problem, prolong the service life of the machine, Luoyang Dahua will introduce four simple methods with better effect from the rust removal methods

Preparation Work before Starting the Jaw Crusher

The Preparation works before starting the jaw crusher are as follows

Five Advantages of Impact Crusher

There are five crushing advantages of impact crusher in the process of crushing

Brief Analysis for artificial sand production line

With economic development, artificial sand production line has been widely used in industries such as water and electricity, urban construction, highway, following Luoyang Dahua Heavy Machinery briefly analysis of the basic processes and performance of the artificial sand production line

Accessories of Sand Washer

The main accessories of sand washer are bearing cover, bearing seat, movable flange, reducer, reducer belt pulley, driven pulley, gear and pinion

Which Aspect Should Be Considered on the Maintenance of Overflow Spiral Feeder?

The maintenance of overflow spiral feeder is of great importance, in this text, we will tell you which aspect should be considered on the maintenance of the feeder

Operation Procedure of Complex Crusher

In this text, we will introduce the operation procedure of complex crusher

What Effect Does Liner Plate Have?

Liner plate is a kind of important part of impact crusher It not only protects the grinding barrel, but also has crushing effect