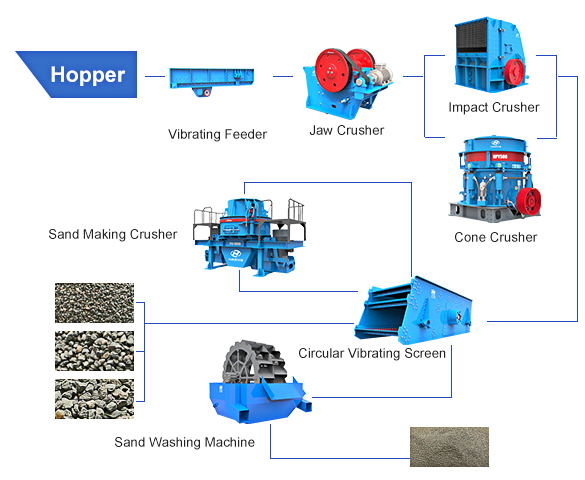

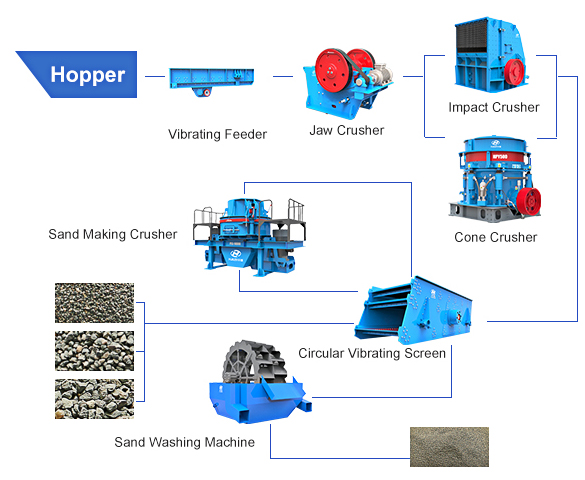

Pebble crushing production line equipment includes jaw crusher, cone crusher, impact crusher, vibrating feeder, vibrating screen, belt conveyor and other equipment. What is the process of pebble stone crushing?

Large river pebbles are uniformly fed into the fine jaw crusher by the vibrating feeder through the bin as raw materials. The stone material meeting the requirements is conveyed by the belt conveyor to the vibrating screen, where it undergoes screening to separate qualified and unqualified materials. The qualified ones are then sent to the river pebble sand making machine for further processing. The unqualified river pebbles will be conveyed back to the fine crushing jaw crusher for re-crushing, and subsequently screened by the screening machine into several different specifications. River pebbles that meet particle size requirements are conveyed to the finished material pile via a belt conveyor. If necessary, river pebbles can be sent to a sand washing machine according to customer needs for cleaning. Any stones that do not meet particle size requirements are returned by the belt conveyor for further processing in the river pebble sand making machine, forming a closed loop of multiple cycles.

Pebble stone crusher manufacturers

01 Equipment Manufacturer:

Look for a reputable manufacturer with a large-scale production capacity. Luoyang Dahua has been focusing on the production of mining equipment for 40 years, with extensive experience and mature technology, making our products more reliable.

02 Device Model:

Users can select the appropriate equipment output based on their requirements and then choose the type of equipment that fits within their budget. Of course, you can also consult our online customer service for your needs, and our expert product managers will provide you with professional answers to any inquiries.

03 After-sales Service:

After-sales service is a crucial link, reputable manufacturers will conduct regular visits and on-site inspections to ensure customer satisfaction and comfort. Luoyang Dahua implements this with great precision, adhering to the service purpose of “prompt response, smooth communication, accuracy and efficiency, reasonableness and thoughtfulness”. After receiving customer requirements, we will promptly contact customers to gain a comprehensive understanding of their specific needs, material composition, scheduled work site and other relevant information. This enables us to provide tailored solutions that effectively analyze and solve problems for our valued clients.