Rod mill relies on the pressure of steel rod and grinding force to break ore. When a steel rod strikes the ore, it first breaks the coarse particles and then grinds the smaller ones. Therefore, the rod mill has selective grinding effect, the product size is more uniform, and less over grinding.

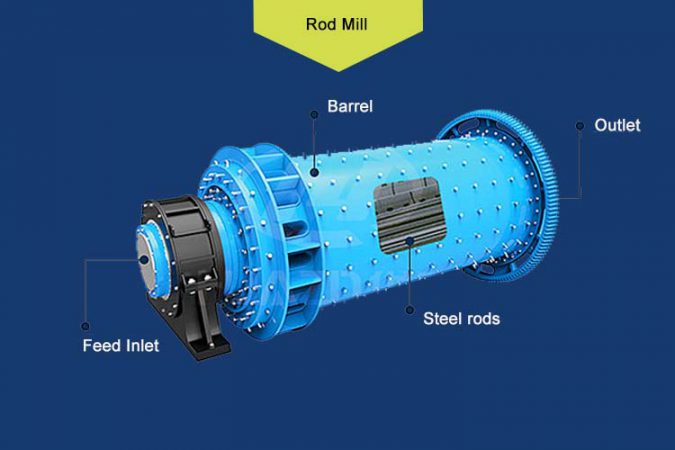

The working principle of dry rod mill is the same as that of wet rod mill. It is driven by the motor and the surrounding big gear driving the cylinder to turn. The cylinder is fitted with a suitable grinding medium – steel rod. Under the action of centrifugal force and friction force, the grinding medium is lifted to a certain height and falls in a throwing or draining state. The ground material is continuously entered into the cylinder by the feed port, crushed by the moving grinding medium, and discharged out of the machine through the overflow and continuous feed force to carry out the next process operation.

What should we do to maintain rod mill?

In general, the rod mill is a grinding equipment that operates 24 hours a day. In working process, the material are fed into the rod mill machine continuously, and the motor drives the cylinder to rotate under the action of the reducer, the steel rod in the cylinder and the material will move together under the action of centrifugal force and friction. The materials fall off under the gravity when they reach the top. The materials after ground are eventually crushed out.

Maintenance is an effective way to extend the life of the machine, so in order to create long-term economic value, the rod mill should pay attention to maintenance in the process of use. We suggest that when the mill runs continuously for a month, all the lubricating oil should be released, the machine should be thoroughly cleaned, and then the new oil should be poured in. In addition, check the lubrication of each part and the oil level height according to the operating specifications. In the process of long-term work of the rod mill, the heat of the transmission bearing is normal, but the temperature should not be higher than 55℃, so as not to burn out parts and lead to strike.