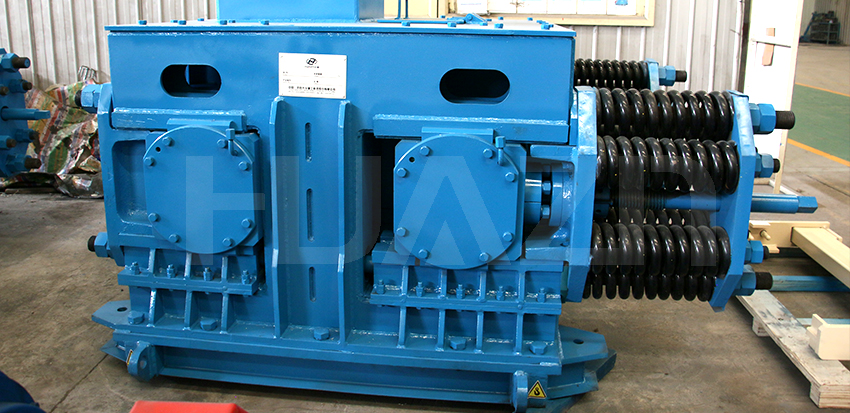

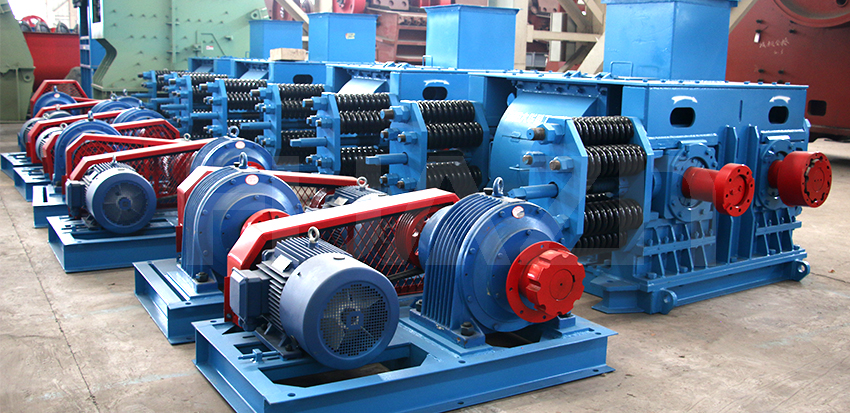

Roll crusher is used in the process of primary, medium and fine crushing as well as rough grinding. Less over crushing granularity is not only the primary advantage of roll crusher, but also the important factor to choose the crusher besides the technical features such as production output, power consumption, working reliability, machine weigh, dimension, etc. The two rollers of roll crusher are driven by the separate motor and do the opposite rotation. The ores are fed from the top of the machine, and are crushed in the clearance that formed between the two rollers.

Roller crusher has the feature of simple structure, reliable working condition, low price, easy maintenance, the crushed products have even granularity, less over crushing, and fine particle size (below 3mm).

Factors on influencing the production capacity of roll crusher

- Material hardness. The more hard the material is, the more difficult to crush and more serious abrasion for the machine.

- Material humidity. The more water is contained, the easier to adhere to the machine and block the discharge transportation, thus reducing the crushing capacity.

- Crushed material fineness. The more fine the crushed material, the less crushing capacity.

- Material composition. The more fine powder contained in the material, the easier to adhere to influence the transportation. Take pre-screen for more fine powder material.

- Wear resistance of crushing machine. The better wear resistance the crushing parts (hammer head, jaw plate) are, the larger crushing capacity.