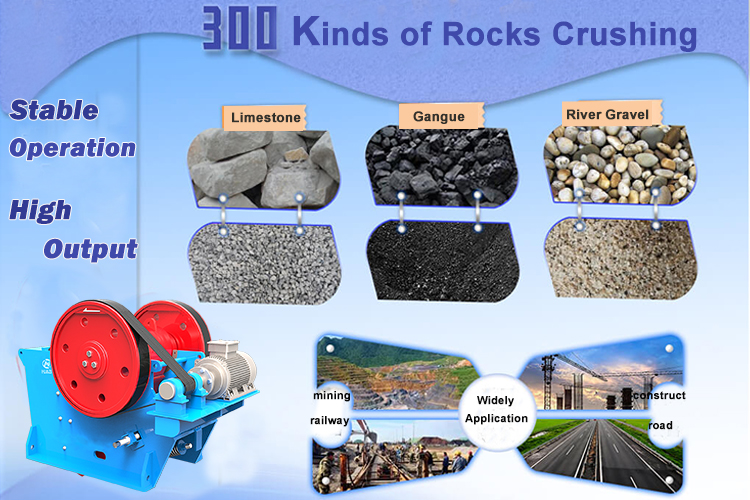

The jaw crusher is widely utilized in the stone industry, primarily for the initial crushing of stones. It breaks larger stones into smaller particles, facilitating subsequent processing. Below are the primary application fields and advantages.

Application fields:

Mining: The jaw crusher is used crushing materials such as granite, marble, limestone, and other ores, preparing them for subsequent processes of fine crushing or grinding.

Sand aggregate production: In the sand and stone production line, the primary crushing equipment is utilized to break large stones into smaller particles, which are subsequently used as essential components in the production of concrete, asphalt, and other building materials.

Road construction: Crushed subgrade materials, such as limestone and basalt, are utilized to produce aggregates that comply with the specified requirements.

Advantages:

High crushing efficiency: Excellent processing capability, ideally suited for large-scale crushing of materials with high hardness.

Simple structure, easy maintenance: Simple design, easy operation and maintenance, reduce downtime.

Adjustable discharge particle size: By adjusting the discharge port, precisely control the particle size after crushing to meet a variety of requirements.

Low operating costs: Low energy consumption, long life of wear-resistant parts, reduce maintenance and operating costs.

Working process

Feeding: Large stone pieces are conveyed into the crushing chamber via the vibrating feeder.

Crushing: The movable jaw plate squeezes the stone to achieve crushing effect.

Discharge: The crushed stone is discharged through the discharge port and subsequently progresses to the next stage of the process.

Type selection

Select according to the material characteristics: The selection of different models is determined by the varying hardness and humidity levels of the stone.

Select according to production demand: Choose the appropriate processing capacity based on the scale of production.

Consider the subsequent process: Select the appropriate discharge particle size according to the requirements of the subsequent process.

The jaw crusher is extensively utilized in the stone industry, featuring high efficiency, durability, and strong adaptability. It serves as a critical piece of equipment in stone processing. A reasonable selection and proper utilization can substantially enhance production efficiency while reducing operational costs.