The vibrating screen is an essential equipment in the sand production line. It is mainly responsible for screening and classifying materials during the crushing process. This vibrating screen is suitable for wet fine grade of difficult-to-screen materials as well as dry screening. It plays a crucial role in linking and transferring throughout the entire crushing operation process. To ensure high-quality aggregates, manufacturers producing sand aggregate need to select a reliable vibrating screen.

What are the uses of vibrating screen in sand making?

1. Material pretreatment. If the particle size of the crushed material varies significantly, it can be screened and classified beforehand to ensure that the feed particle size meets the standard. Additionally, for materials with relatively small particle sizes, a preliminary screening before crushing and sand-making can help reduce the amount of mud powder in the crushed material.

2. Second screening. After undergoing primary and secondary crushing, the material needs to be further screened and graded. The particles that meet the processing standard will proceed to the next stage for crushing or sand making, while those that do not meet the standard will undergo additional crushing until they reach the required particle size for entering the next processing phase.

3. Sieve the mud powder. After the process of sand making, it is common practice to wash the material and mix the sludge powder with the wastewater from sand washing. To recover the fine sand and dust that are lost during this process, a vibrating screen can be installed to sieve, classify, and collect the sludge powder in the sedimentation tank.

Vibrating screen recommendation

The sand and stone production line commonly uses both round vibrating screens and linear vibrating screens. The vibrating screen can have one, two, three, or four layers, allowing users to choose according to their specific materials. This provides a wider range of options for selection.

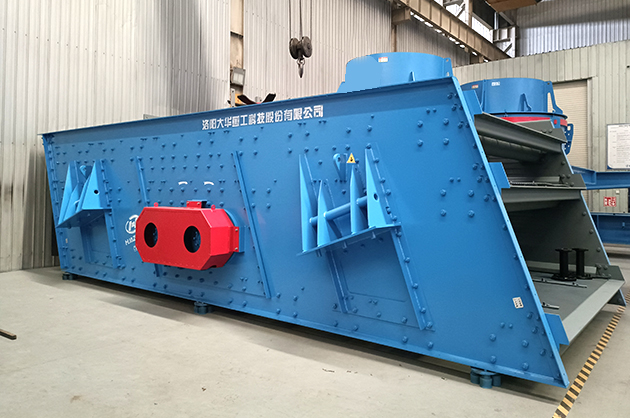

◆ YKR series vibrating screen

The YKR vibrating screen is a round vibrating screen that can be customized to meet different customer needs, offering options of one layer, two layers, three layers or multiple layers for screening. It can be used for both dry and wet operations. The circular vibrating screen utilizes the centrifugal force generated by the rotating eccentric block in the vibrator to create a continuous circular or nearly circular motion of the screen box and other components. It boasts reliable structure, high screening efficiency, strong vibration force, durability, easy maintenance and safe operation. It is widely applied in mining, building materials, transportation, energy, chemical and various other industries.

◆ ZKR series vibrating screen

The ZKR vibrating screen is a linear vibrating screen designed for dehydrating and desliming materials. It comes in both single-layer and double-layer types. The linear vibrating screen utilizes vibration motor to generate force, causing the material to be thrown up on the screen and move forward in a linear motion. With optimized vibration parameters, it ensures stable movement, low energy consumption, high output, as well as efficient screening and dehydration.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.