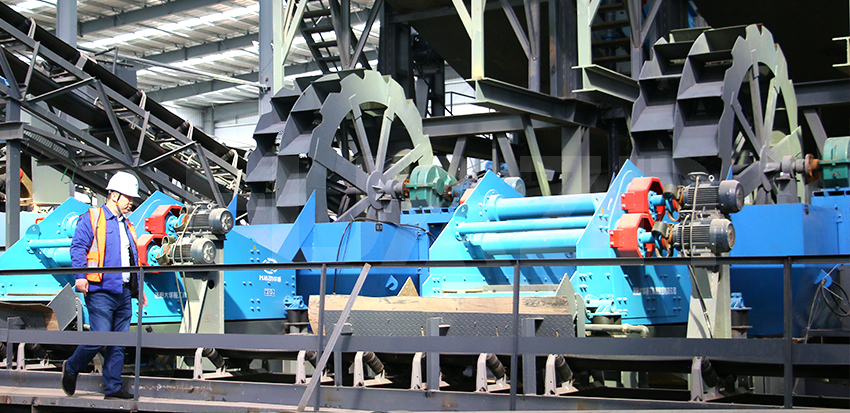

Bucket wheel sand washer is used for washing and dewatering of construction sand gravel, and is typically operated in conjunction with sand making machine to produce washed artificial sand. A 200 tph sand washer machine can effectively remove the stone powder and impurities mixed in the sand gravel, helping to enhance the quality and value of the final products. As a result, it has become a popular choice among medium and large-scale sand washing operations. What models are available for 200 tph sand washer machine?

Types of 200 tph sand washer machine

There are many types of bucket wheel sand washer machine, each with different production capacity. To help you make the most suitable choice and avoid unnecessary waste, we recommend selecting a model based on your project’s specific needs—such as required production capacity, material particle size, impurity levels, and desired cleanliness of the final product.

The common used 200 tph bucket wheel sand washer machine is DXS3615 and DXS4215. DXS3615 bucket wheel sand washer production capacity is 150-200 t/h, power is 11 Kw; DXS4215 bucket wheel sand washer is 200-250 t/h, power is 15 Kw.

This sand washing equipment features a simple, reliable design and offers an affordable solution for your operations. It can be used as a single unit or in parallel with multiple units to enhance production capacity and cleaning rate.

How does the bucket wheel sand washer work?

When the sand washer works, electromotor drives the impeller rotate slowly through V-belt, reducer and gear. The sand and stone materials are fed into wash trough through feeding chute which are driven by the impeller to overturn and grind with each other in order to remove the impurity covering on the sand surface, at the same time destroy its moisture layer. Fill certain amount of water. The impurity and foreign matters with small proportion are discharged from the wash trough, while the clean sand and stone are taken away by the impeller, and finally are poured into discharge chute to complete washing process.

How much water does a bucket wheel sand washer machine consume approximately per hour?

Based on calculations, approximately 2 to 3.5 tons of water are required for sand washing without recycling. However, if water is recycled, only about 0.1 tons of water are needed to clean one ton of sand. When using a wheel bucket sand washing machine, the water consumption is generally related to the equipment model—larger models with higher output capacities typically require more water for the effective cleaning of stone materials.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.