The wet production process refers to the use of water washing in the process of material crushing and screening, and the washing operation of coarse and fine aggregate is carried out with the sand washing machine and sand spiral classifier. Wet processing technology is generally used when the raw material contains mud or soft particles.

The traditional wet sand production process also has many problems, such as large amount of wastewater and crude product fineness modulus. However, the manufactured sand produced by this process has a round appearance and beautiful quality. High quality manufactured sand means that there are reasonable requirements and proportions in gradation, grain type and powder content, while high quality manufactured sand particles are usually clean and contain less powder.

With the aggregate industry gradually transitioning from the original extensive operation to the direction of fine management, sand and stone production also pays more attention to the resource recovery and utilization rate and the control of mud content. For example, for the traditional wet sand process, there will be water pollution, low output of finished sand, and too high moisture content. Until now, there are corresponding solutions to these problems.

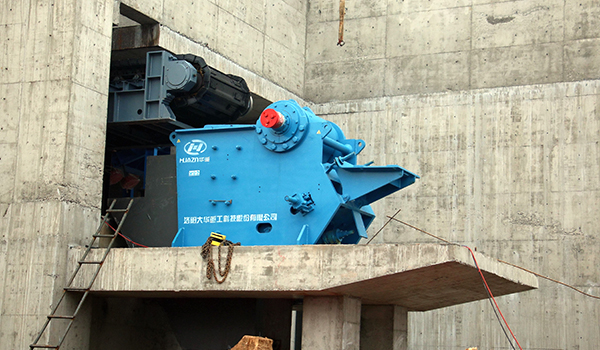

Take the 800t/h granite crushing sand production project of Luoyang Dahua as an example. The sand aggregate production line adopts the wet production process, raw materials after coarse jaw crusher crushing are transported to large stock pile, the materials are crushed by cone crusher in the stock pile, and then shaping and screening by sand making machine, to ensure that the size and the shape of finished aggregate. The stone wet production process is equipped with sand washing machine and sewage treatment system, can effectively reduce the mud powder content of finished sand, less dust generated in the production process, and the finished product has good appearance and high cleanliness.