Sand making machine is key equipment for the production of artificial sand and stone, which can be classified into various types based on different working principles and application fields. The following outlines the standard classification of sand making machines.

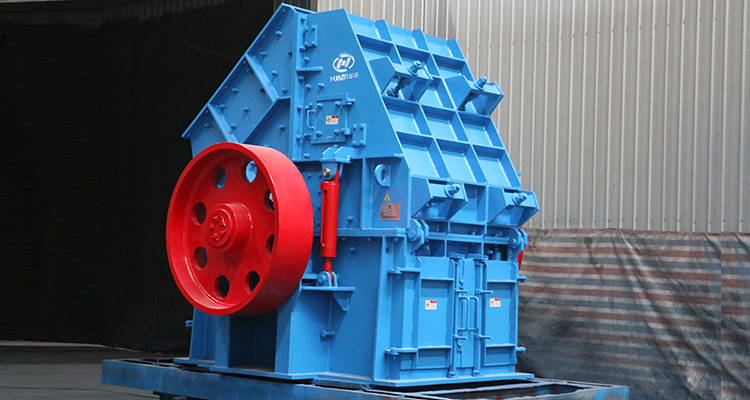

★ Hammer crusher

The hammer crusher utilizes a high-speed rotating hammer head to crush raw materials and is suitable for medium-hardness materials, such as limestone and gypsum.

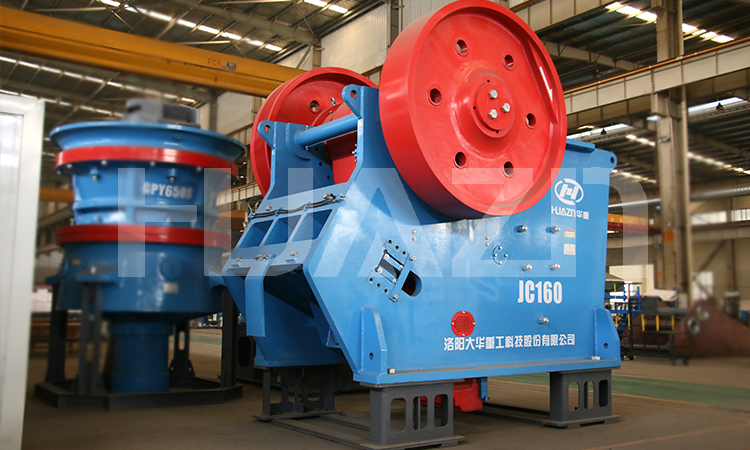

★ Jaw crusher

The jaw crusher breaks the raw material through extrusion and friction between two jaw plates, making it suitable for ores with higher hardness.

★ Cone crusher

The cone crusher utilizes a rotating cone head in a conical crushing chamber to compress and fracture raw materials, often employed for materials with moderate hardness, such as granite and basalt.

★ VSI sand making machine

The VSI sand making machine utilizes a vertical shaft rotating device to generate crushing effect through the impact between the high-speed rotating rotor and the stones. It is widely employed in manufacturing high-quality artificial sand. By optimizing the rotor design and the structure of the crushing chamber, it can achieve higher crushing efficiency and a better shape for the finished product.

The choice of sand making machines depends on factors such as the hardness of the raw material, particle size requirements, production capacity, and application field. The different designs and working principles of sand making machines determine their advantages and application ranges in various scenarios. For users who need to produce sand with specific specifications and shapes, selecting the appropriate type of sand making machine is crucial.

The understanding of sand making machine classification enables users to select the appropriate equipment based on their production needs and material characteristics, thereby enhancing production efficiency and output quality.