The crusher machine that commonly used in the mining industry is jaw crusher, cone crusher, and impact crusher, etc. The main parts of these machines are jaw crusher tooth plate, toggle plate, eccentric shaft, cone mantle & concave, hammer crusher hammer head, and other components. Today, we will introduce the main parts of jaw crusher, cone crusher, and impact crusher.

Jaw crusher jaw plate

Jaw plate is composed of movable jaw plate and fixed jaw plate. Luoyang Dahua jaw plates are made of high manganese steel (Mn13, Mn18), and manganese chromium alloy (Mn13Cr2, Mn18Cr2). The jaw plate has strong wear resistance, longer service life.

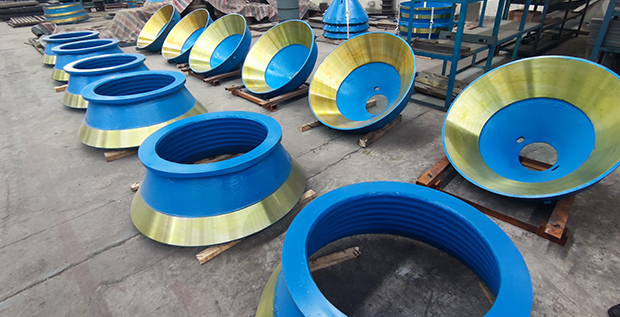

Cone crusher mantle & concave

The mantle is installed over the head/cone, which is mounted onto main shaft. The mantle forms part of the replaceable wear surfaces and it oscillates with the moving shaft (moving wear surface). Mantles are typically manufactured from manganese steel alloy.

A concave ring (bowl liner) is housed within the upper casing; it forms the stationary wear surface.

Impact crusher blow bars

Blow bars are used in horizontal shaft impact crushers by inserting them into the rotor. The main material is high chromium cast iron and high manganese steel. Luoyang Dahua can provide multi models of blow bars, please bring your drawings to contact us.

Luoyang Dahua is a professional manufacturer of mining equipment, boasting advanced technology, reliable quality and rich production experience. It offers users a wide range of high-quality equipment, recommends suitable and reasonable equipment based on their needs, and provides guidance during installation and commissioning at the production site to ensure smooth production. If you don’t know how to choose the crusher machine, please contact our Online Service to get customized solution.