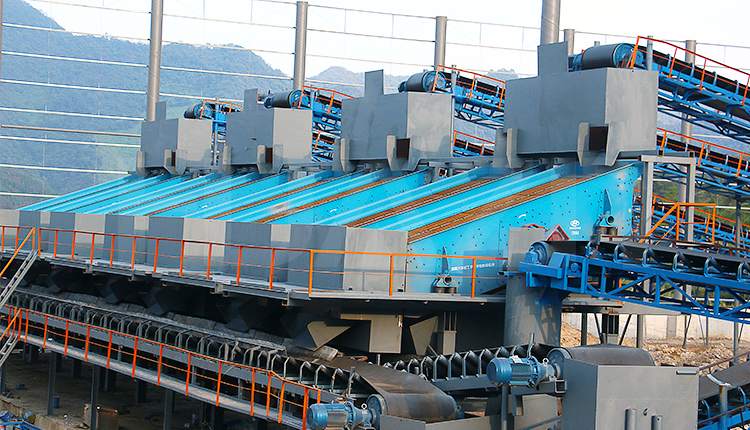

Vibrating screen is an important equipment in stone crushing production line. In this text, we will analysis the reasons for poor vibrating effect of vibrating screen.

1, The sieve hole is blocked

When the feed material has high mud and water content, it can cause material adhesion and screen blockage. The sieve hole should be cleaned first at this stage, followed by appropriate adjustments to the water spray volume and screen surface inclination.

2, The sieve pore wear is serious

When the sieve mesh is used for an extended period of time, it will result in serious wear and tear on the screen mesh, thereby severely impacting its screening efficiency. In such cases, it is necessary to repair the worn-out screen; however, if the wear becomes extremely severe, replacing the sieve mesh becomes imperative.

3, The feeding is not uniform

When the feed tank of the vibrating screen is too narrow, the material cannot be evenly distributed along the entire screen surface, so that the screen surface cannot be effectively used, which will affect the screening effect. At this time, the width of the feed tank should be adjusted to make the feed of the screen uniform.

4, The material on the screen is too thick

The excessive thickness of the material on the screen may be attributed to an increase in feed quantity, screen hole blockage, and a slight inclination of the screen surface. In such cases, adjustments should be made based on specific circumstances.

Luoyang Dahua can provide horizontal screen, YK series vibrating screen, NS series vibrating screen. The YK series vibrating screen has reliable structure, strong exciting force, high screening efficiency, low vibration noise, easy maintenance, safe use and other characteristics. This vibrating screen is widely used in mining, building materials, transportation, energy, chemical and other industries of product classification.