Granite is widely used as a building material due to its high hardness and wear resistance. Which crusher should be used for crushing granite? What are the types of granite crushers? This article will provide you with detailed information.

What crusher is used to break granite?

Considering the hardness characteristics of granite materials, which type of crusher is more suitable for crushing granite? There are also various types of granite crusher equipment available.

| Type of Crusher | Crushing method | Type of production |

| Jaw Crusher | extrusion crushing | primary crushing/head breaking |

| Cone Crusher | laminated crushing | second stage medium/fine crushing |

| Impact Sand Making Machine | Impact crushing | three stage fine crushing/sand making |

Primary Crushing: Jaw Crusher

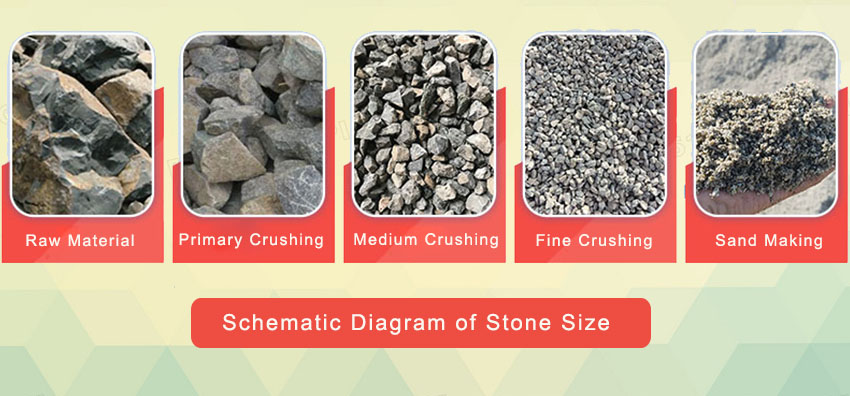

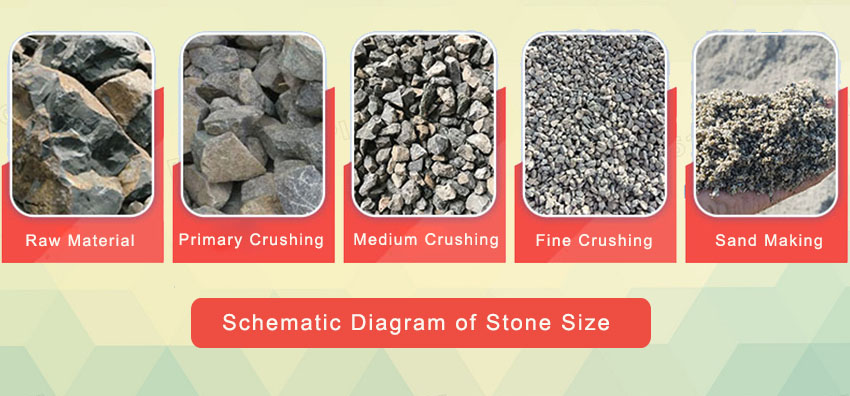

Jaw crusher can break the stone with hardness about 6%, especially granite. This type of stone is more suitable for extrusion crushing, which reduces abrasion and improves crushing effectiveness.

Fine Crushing: Cone Crusher

After primary crushing, the granite needs to be crushed finely again in order to meet the stone specifications required for construction production. Therefore, the cone crusher is more suitable as a fine crushing equipment. Through extrusion crushing and laminating crushing methods, the cone crusher finely breaks the granite. It has a multi-cylinder design, with an over-iron protection device on the cone of the cavity cylinder, which can protect the equipment itself and reduce wear and failure when crushing granite.

Sand Making Machine: Impact Sand Making Machine

Granite can not only be broken into building stones, but it can also be used to make construction sand. Therefore, a granite sand making machine – impact sand making machine – will be utilized. After fine crushing of the granite, it will then be processed by the sand making machine into 1-5mm specifications of mechanical sand.

Granite crushing production line configuration scheme

Scheme one: feeder + jaw crusher + cone crusher + vibrating screen + conveying equipment

Scheme two: feeder + jaw crusher + cone crusher + sand making machine + vibrating screening + conveying equipment

Scheme 3: feeder + mobile crushing station + jaw crusher/cone crusher + vibrating screening + conveying equipment

Granite crusher machine manufacturer

Here, more customers choose Luoyang Dahua granite crusher, because the company completes the entire process from raw materials to finished products. As a result, the price of a granite crusher can be discounted by about 10%-20%. If you want to know more about the granite crusher or the configuration, please consult the Online Service. Our real-time online personnel are available to provide you with detailed answers. Please request a quote online.