The performance differentiation of sand crushing and screening products varies greatly. For investors who have recently entered the sand processing industry, the most critical issue is to choose equipment that can achieve the expected output value and provide higher cost performance. What crusher machine is used to break hard stones?

Hard stone crusher – cone crusher

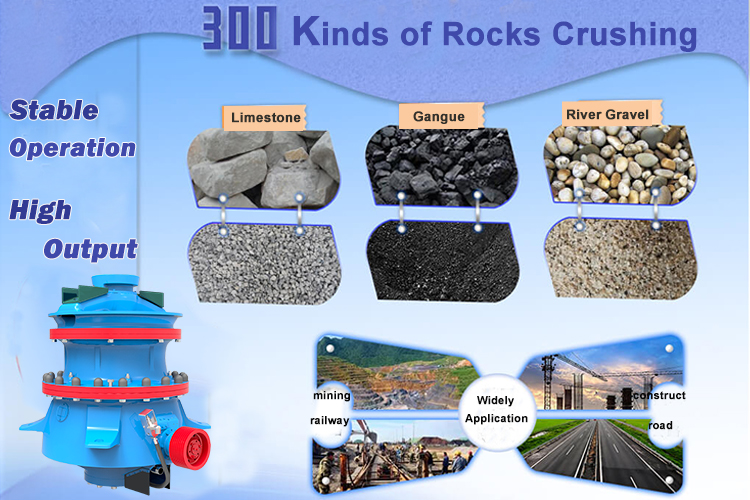

Cone crusher is one of the most commonly used crushing equipment, and its main components include a host frame, pulley, hydraulic cylinder, fixed cone, moving cone, spindle, drive shaft and eccentric sleeve. Cone crusher is suitable for large and medium-sized stone processing enterprises, machine-made sand processing enterprises, construction solid waste recycling, and tailings regeneration aggregate. It can achieve the crushing, fine crushing, and ultra-fine crushing of high hardness materials such as river pebbles, granite, and basalt.

The cone crusher features low energy consumption and a powerful crushing force. It is known for its high reliability, large production capacity, advanced automation, user-friendly operation and maintenance, excellent product grain shape, and cost-effective wearing parts. The laminated crushing of cone crusher enhances the crushing effect, especially for stones with high hardness. There are four types of cavity available: super coarse, coarse, medium, and fine. The principle of cone crusher selection is based on the size of the feed and the discharge grain. When the feeding degree is high, resulting in a coarse product particle size, it is recommended to choose an extra coarse or coarse type. Conversely, when aiming for a medium or fine product particle size, it is advisable to select a medium or fine type.

Cone crusher advantages

1, The intelligent constant crushing chamber system design enables the crusher feed opening and discharge opening to maintain their size for a long time, while keeping the crushing chamber type unchanged.

2, The intelligent automatic control system of cone crusher records the actual production load, motor power, and temperature inside the equipment throughout the entire process. It also automatically optimizes and adjusts crusher settings.

3, The use of a positive pressure dust-proof system helps eliminate dust pollution inside the equipment, effectively prolonging cone crusher service life and reducing maintenance costs.

4, Automatic design, users don’t need to stop. It automatically adjusts the discharge opening to remove any foreign objects. Additionally, when the machine is overloaded, the motor stops automatically through thermal protection to prevent damage from overloading.

5, The main shaft is supported by two points to create a double support structure, enabling it to withstand greater crushing force. The moving cone has a small eccentric angle, ensuring better stability and increased processing capacity.

The reason of the selection of cone crusher for hard stone

The working principle of the ordinary crusher is to use a hammer head to roll and impact the stone, resulting in a change in its appearance. However, this machine has a relatively low crushing ratio and takes a longer time to operate. Additionally, it experiences significant wear and tear. The appearance of the cone crusher has changed this mode, in the process of operation, the motor drives the machine to rotate, causing the hammer to swing and crush incoming ore repeatedly. This working principle significantly enhances efficiency while minimizing damage to the machine.

Luoyang Dahua has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service. If you are interested, please consult the Online Service or by Whatsapp +86 13938852499.