Iron ore belongs to high hardness metal ores. In the choice of crusher, generally choose the crusher suitable for the crushing of hard materials, such as jaw crusher, cone crusher, and impact crusher, etc. In the crushing process, generally adopt coarse crushing, medium crushing, and fine crushing three crushing processes, through crushing into the later grinding stage, to achieve more breaking and less grinding, improve production efficiency.

Iron ore production line

1.Jaw crusher is generally used for the coarse crushing of iron ore, suitable for crushing 700-800mm large ore to 200-300mm below, with the characteristics of large crushing ratio, wear resistance and low energy consumption. The production capacity of jaw crusher is 50-1000 t/h.

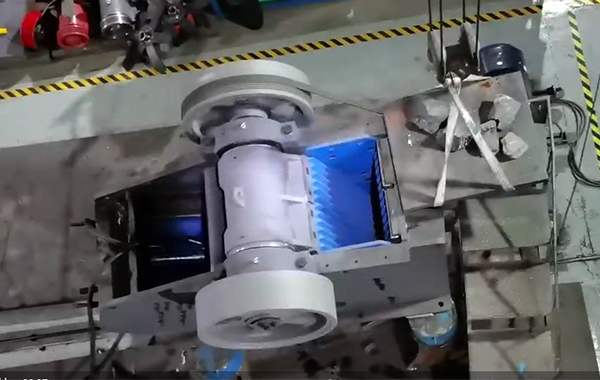

2.In the crushing stage, cone crusher is for hard material crushing, which is welcomed by the industry. On the one hand, the equipment is wear-resistant and intelligent, and on the other hand, the finished product size and output are considerable. Cone crusher production is 700-800 t/h, the 300mm stone can be processed into 50mm below, including single cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher.

3.In the fine crushing stage, impact crusher is selected for fine crushing to meet the needs of subsequent grinding. The impact crusher is mainly used for fine crushing, with a production capacity of more than 50-600 t/h. Impact crusher adopts impact crushing, stone less than 50mm can be processed to less than 5 mm. Here we recommend Luoyang Dahua Heavy Industry PLS vertical impact crusher.

Iron ore crusher mainly includes jaw crusher, cone crusher and impact crusher. Specific model selection can be configured according to the production capacity and finished product requirements. If you don’t know how to choose the iron ore crusher, please contact us at any time. Whatsapp: +86 13938852499