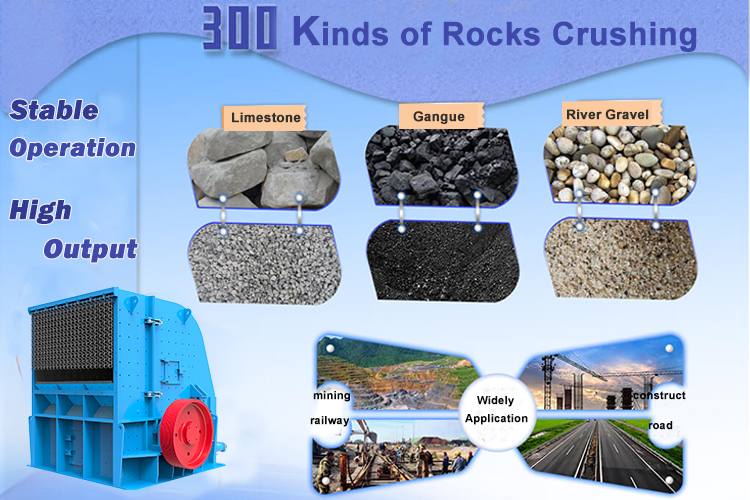

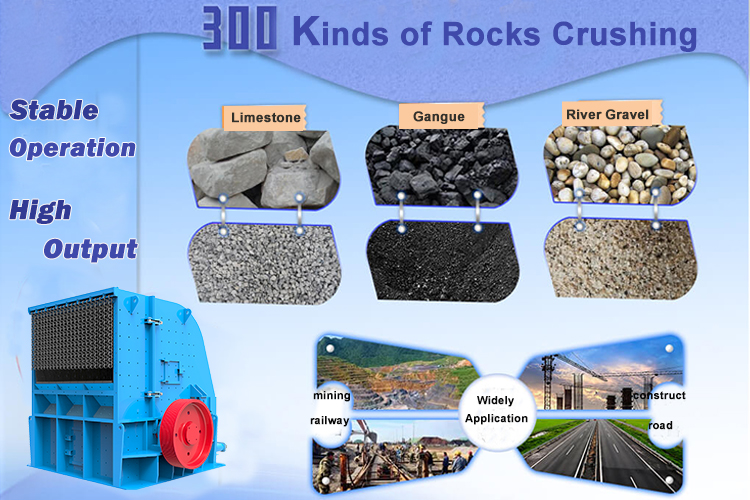

Choosing the right impact crusher is a critical decision for quarry, mining companies, and recycling facilities. Based on frequent inquiries from our clients, we have compiled the key areas of concern and provided clear explanations to guide your selection process.

1. Feed Material Characteristics

Customer Question: “Will this crusher handle my specific type of rock/recycled concrete/asphalt?”

Answer: The composition, hardness, abrasiveness, and moisture content of your feed material are the primary determinants. Impact crushers excel at processing medium-hard to hard materials with low to medium silica content. For highly abrasive materials (e.g., granite with high quartz), the wear costs may be significant. Always provide your supplier with a detailed material analysis, including:

Compressive Strength (MPa or psi)

Abrasion Index (e.g., Los Angeles value)

Maximum Feed Size and Gradation

Moisture or Clay Content

2. Required Final Product Specifications

Customer Question: “Can I achieve my desired product shape and multiple grading sizes with one machine?”

Answer: Absolutely. The main advantage of impact crushers is their ability to produce a well-shaped, cubicle product—essential for high-quality concrete and asphalt aggregates.

Modern machines offer excellent adjustability

Adjustable Rotor Speed and Impact Force: Influences fragmentation and product shape.

Hydraulic or Mechanical Adjustable Grinding Path/Appron Gap: Allows precise control over the top product size.

Two or Three-Curtain Configuration: Enables production of two or three specified fractions in a single pass, enhancing versatility.

3. Capacity and Power Requirements

Customer Question: “What is the guaranteed throughput (TPH) for my material, and what power plant do I need?”

Answer: Capacity depends on material characteristics, feed size, and desired reduction ratio. Manufacturer brochures state maximum capacities under ideal conditions. For a realistic guarantee, discuss your exact scenario. Power requirements correlate with capacity and material hardness. Ensure your electrical infrastructure can support the crusher motor, which can range from 200 kW to over 800 kW for large primary units. Properly sizing prevents under-performance and reduces energy waste.

4. Wear Parts, Maintenance, and Operational Costs

Customer Question: “How often do I need to change hammers/blow bars and liners, and how complex is the maintenance?”

Answer: This is a major focus. Operational costs are driven by wear part consumption and service time.

Wear Part Material & Access: Blow bars (hammers) and impact plates are key consumables. Machines designed for easy access (e.g., hydraulic opening housings) drastically reduce downtime for replacement. Choose wear part alloys (e.g., high-chrome, martensitic steel) based on your material’s abrasiveness.

Rotor Design: A robust, monolithic rotor is often preferable for heavy-duty use due to its durability and higher inertia.

Standardization: Using standardized, readily available parts minimizes inventory costs and delivery waits.

5. Automation and Modern Control Systems

Customer Question: “How can I optimize performance and protect the machine?”

Answer: Modern crushers are intelligent. Key features include:

PLC-Based Control Systems: Allow easy adjustment and monitoring of key parameters.

Automatic Rotor Speed Adjustment: Optimizes performance for varying feed conditions.

Hydraulic Gap Adjustment: Enables remote, precise product size changes.

Safety & Protection Features: Look for systems that prevent start-up under load, monitor bearing temperature and vibration, and automatically reverse the rotor in case of a blockage.

Selecting an impact crusher requires a careful evaluation of your specific needs against the machine’s capabilities. Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.