The vibrating screen is composed of a screen mesh and vibrator, which serves as important equipment in the sand production process for screening, classifying, removing impurities, and filtering. The selection of vibrating screen directly affects the product grade and yield. The vibrating screen is mainly classified into three categories: circular vibrating screen, high frequency screen, and mobile screening machine.

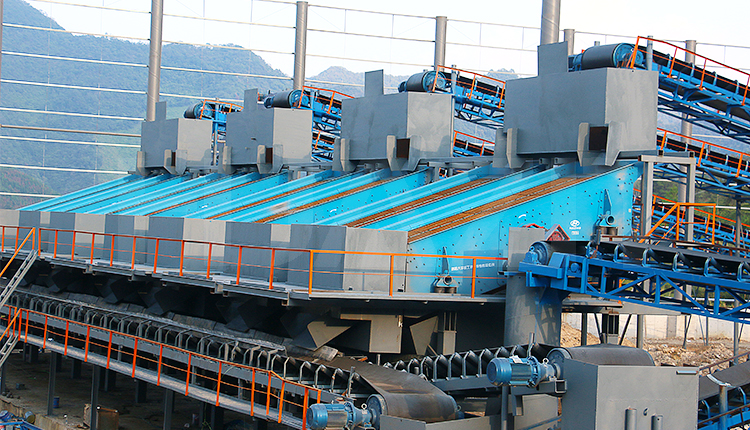

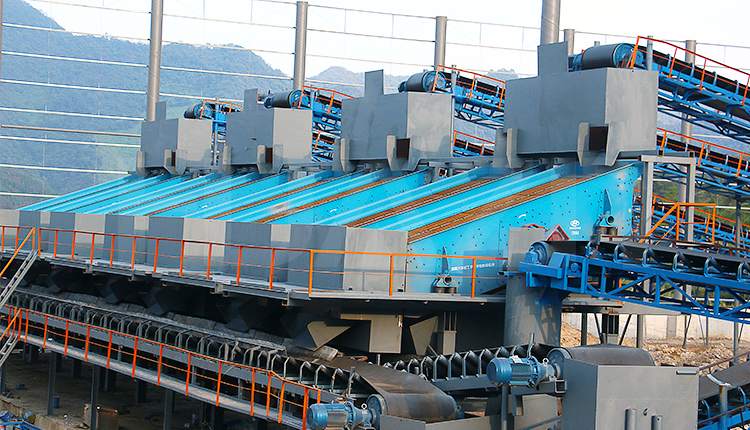

The circular vibrating screen is a new type of vibrating screen that features circular vibration, multiple layers, and high efficiency. It is widely used in the mining, building materials, transportation, energy, chemical, and other industries for product classification.

What is the capacity of a vibrating screen per hour?

The YKR series vibrating screen is the most commonly used circular vibrating screen. This equipment can provide a one-layer, two-layer, three-layer, or multi-layer model vibrating screen according to different customer needs. It can be used for dry or wet screening operations.

YKR Series vibrating screen advantages:

1, The vibrating screen adopts a block eccentric external modular integrated design, which can be lubricated with grease or thin oil for automatic lubrication. This enables the equipment to have a large capacity, high screening efficiency, and strong processing capability. The vibrating screen can also quickly adjust the amplitude of the vibration screen by increasing or decreasing the number of standard counterweight blocks. The frequency, amplitude, and angle of the vibrating screen can be adjusted to ensure higher screening efficiency.

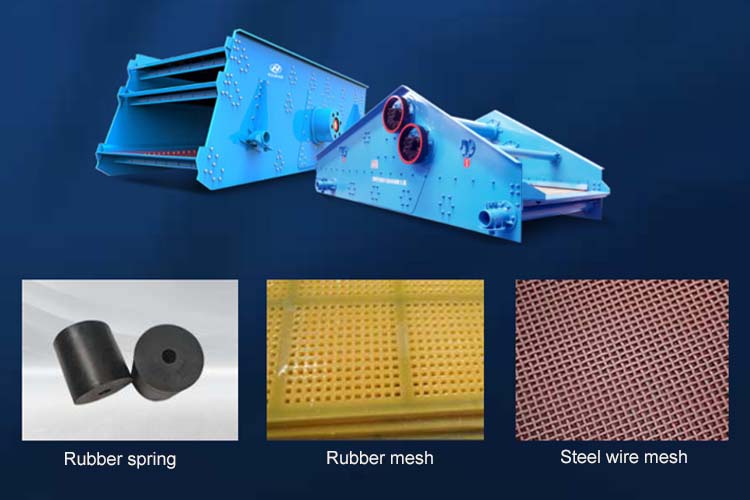

2, To meet the requirements of various classification operations after coarse crushing and medium and fine crushing in the crushing process, users can select a variety of screens such as tensioned modular steel wire screens and polyurethane screens with different diameters. Different production needs can be met through a simple screen replacement operation.

3, The use of structures with small amplitude, high frequency, and large inclination results in higher screening efficiency and larger processing capacity for the machine. The side panel is flanged and connected to the beam and support seat using high-strength bolts, ensuring that the entire screen has no welding fatigue stress.

4, The use of vibration suppression technology helps to prevent start and stop caused by resonance from lateral shaking. The vibration spring used is a composite rubber spring, which ensures stable vibrations and low noise.

5, An optional vibrating screen dust sealing device is installed to prevent dust from flying, ensuring high environmental performance.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. Our company not only guarantees the products quality, but also provides perfect after-sales service. Luoyang Dahua has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.