The common sand production line typically consists of vibrating feeders, coarse crushing equipment (jaw crusher), medium and fine crushing equipment (impact crusher or cone crusher), sand making machine, belt conveyor, vibrating screen, and other equipment. However, some sand production lines may also include sand washing machine to effectively clean the soil and debris in the sand, thereby improving its market application.

When should I consider adding a sand washing machine?

1, If the sand and stone aggregate needs to be clean, a sand washing machine should be used. If the artificial sand itself contains a small amount of soil, combined with the violent collision of stones, it will inevitably produce some stone powder. If the content of stone powder exceeds the standard for construction sand, it needs to be cleaned in order to meet the standard. Therefore, it is necessary to equip sand washing machine.

2, The production line should be built in close proximity to a water source, preferably utilizing natural sources such as rivers or lakes for sand washing. This not only reduces investment costs but also ensures the essentiality of water in the process.

3, The production line in some areas with high environmental protection requirements must be equipped with dust removal and noise reduction devices. Additionally, sand and stone lines often need to be equipped with sand washing machine to reduce dust pollution.

The commonly used sand washing machine includes the spiral sand washing machine and the bucket wheel sand washing machine. Both of these types have their own advantages, serving the purpose of cleaning the sand by removing soil and dust. The choice of a specific sand washing machine should be determined based on individual circumstances.

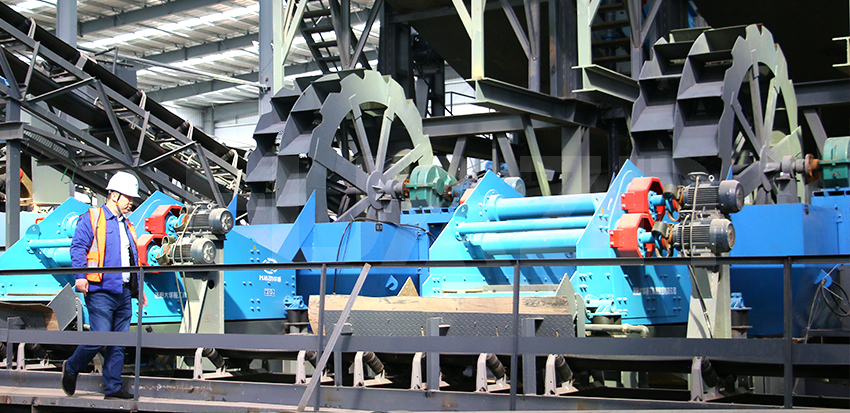

DXS bucket wheel sand washing machine

The bucket wheel sand washing machine is a commonly used equipment in the sand and stone industry for washing sand. Its unique design enables the recycling of water resources, promoting environmental protection and energy conservation. Additionally, it features wear-resistant lining plates around the impeller to reduce friction between materials and increase equipment lifespan.

XL spiral sand washing machine

The series of sand washing machine can be categorized into single spiral and double spiral structures based on the amount of cleaning materials. Additionally, they can be classified as light or heavy depending on the particle size of the washing material. The light sand washing machine is suitable for fine-grained materials below 10mm, while the heavy sand washing machine is designed for coarse-grained materials ranging from 10-80mm.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.