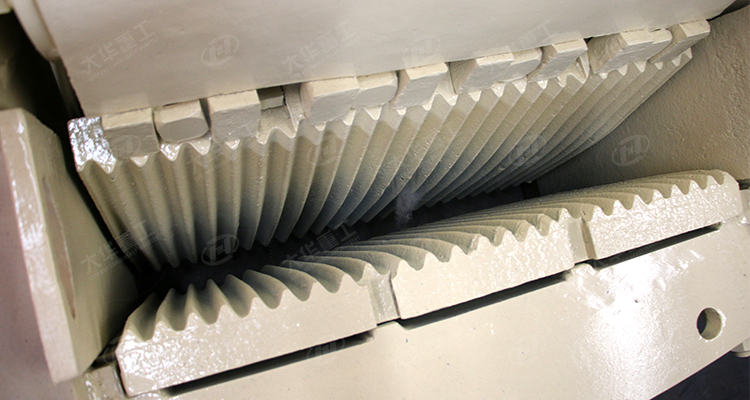

The jaw crusher tooth plate is commonly known as the jaw plate, which can be further divided into the fixed jaw plate and the movable jaw plate. It serves as the main component of a jaw crusher. When the jaw crusher is in operation, the movable jaw swings back and forth with the eccentric shaft, while the fixed jaw plate forms an angle to squeeze the stones. Therefore, the jaw plate is also a vulnerable component of the jaw crusher. The service life of the jaw plate primarily depends on the duration of production and the extent of damage, which also varies for different materials.

How frequently should the jaw plate be replaced?

The jaw crusher jaw plate generally needs to be replaced once a year, but the frequency may vary depending on the hardness of the materials being crushed. The JC series jaw crusher from Luoyang Dahua Heavy Industry offers optional jaw plates, ensuring excellent crushing performance. The design includes a protective plate and high-wear-resistant movable jaw with different tooth options for various materials, resulting in improved crushing efficiency. Additionally, a heavy protection plate is installed above the movable jaw to prevent material impact and effectively safeguard the integrity of both the movable jaw and its internal bearings.

JC jaw crusher fixed jaw plate structure

The fixed jaw plate is divided into three pieces, with a single weight of 1616Kg. This design makes it more convenient to replace the wearing parts. The middle tension bolt does not need to be removed; you can simply lift the jaw plate out since the bolt is hidden underneath it, ensuring minimal wear and tear.

The fixed jaw plate can theoretically be adjusted up to 12 times, whereas the original structure can only be adjusted once.

JC jaw crusher movable jaw plate structure

The movable jaw plate is divided into two pieces, with each piece weighing 1730Kg. It is convenient to replace the wearing parts as the middle tension bolt does not need to be removed. The jaw plate can simply be lifted out, and the bolt is hidden underneath it, preventing any wear.

The movable jaw plate can be theoretically adjusted up to 8 times, whereas the original structure allows for only one adjustment.

Second, how to increase the service life of the jaw plate?

1, The quality of the jaw crusher jaw plate is generally suitable for high manganese steel material. When selecting a jaw plate, it is important to observe whether there are any pores on the surface. Some foundries may produce jaw plates with numerous pores due to improper handling during the manufacturing process, which can result in reduced durability. The jaw plate may become seriously deformed, bent, or broken after prolonged use. Therefore, it is important to choose a high-quality original jaw plate when considering replacement.

2, The material is not regularly sampled because factors such as the composition, hardness, and mud content of the material affect the performance and service life of the jaw plate. Therefore, it is necessary to remove foreign bodies and high hardness materials in advance or adjust equipment parameters to ensure safe production conditions.

3, Please carefully inspect the connecting parts of the equipment for any looseness or abnormalities, and ensure that the bolts and nuts are securely tightened before using.

4, No production overload, no production fatigue, etc.

The jaw plate of the jaw crusher must be selected for good wear resistance in order to ensure its service life. Additionally, proper maintenance and care should be given to the jaw plate during use, which can reduce wear during production and extend its lifespan.