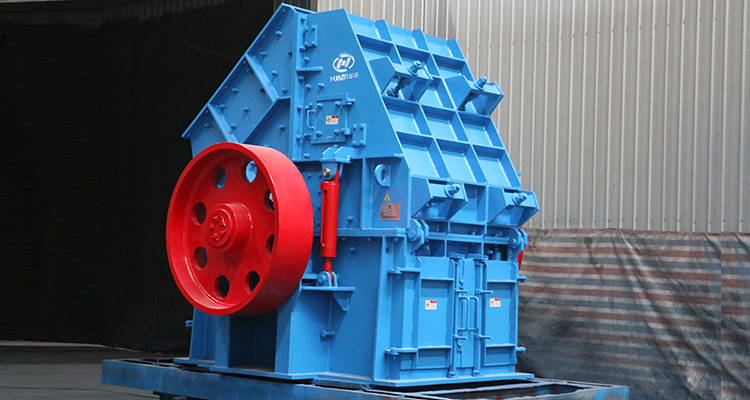

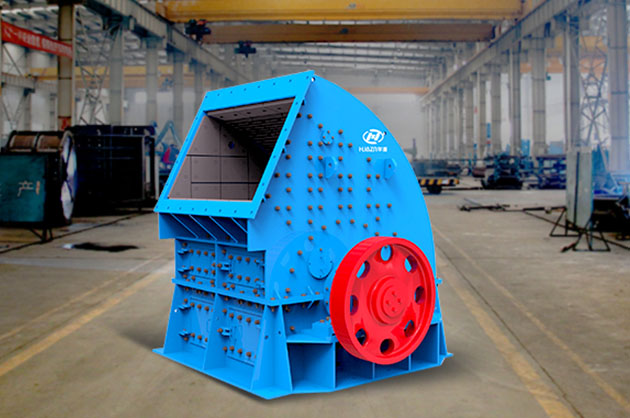

A hammer crusher operates on the principle of impact. Rapidly rotating hammers strike the incoming material, shattering it against hardened breaker plates. This mechanism makes it highly effective for a wide range of materials.

What rock can a hammer crusher break?

Limestone and Other Medium-Hard Rocks: This is the primary application. Hammer crushers excel at processing limestone, gypsum, coal, and other sedimentary rocks with compressive strength below 200 MPa. Their ability to achieve a high reduction ratio in a single stage makes them a top choice for cement plants and limestone quarries.

Brittle Materials: This includes coal, salt, chalk, alum, brick, and tile. The crusher pulverizes these materials efficiently without excessive wear on the hammers.

Recyclable Construction Waste: In the recycling industry, hammer crushers are invaluable for crushing concrete, asphalt, and demolition debris. They can easily handle the mixed composition of these materials, separating rebar and other metals that can be removed by magnets later.

How to chooser hammer crusher?

According to the production demand of the sand and gravel plant, if the output is large, the heavy hammer crusher is naturally the main choice. Select the corresponding equipment based on the model of the equipment. This can ensure that the output meets the standard and avoid blindly choosing equipment and spending unnecessary money

Choose based on the type of hammer crusher manufacturer. Factory direct sales are better because they have their own processing workshops and do not go through middlemen. Therefore, they can save more costs in raw material production and offer lower hammer crusher prices than middlemen.

Hammer crusher price

The price of hammer crushers is determined by the type of hammer crusher. The price ranges from $5,000 – $50,000.

Small Models (Capacity: 5-20 TPH):

Ideal for small-scale operations, laboratories, or specialized recycling.

Price Range: $5,000 – $20,000 USD.

Medium Models (Capacity: 50-200 TPH):

The workhorses for most aggregate and limestone processing plants.

Price Range: $25,000 – $100,000 USD.

Large & Mobile Models (Capacity: 300+ TPH):

Used in large-scale mining and major construction projects. Mobile units with their own chassis are the most expensive.

Price Range: $150,000 – $500,000+ USD.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.