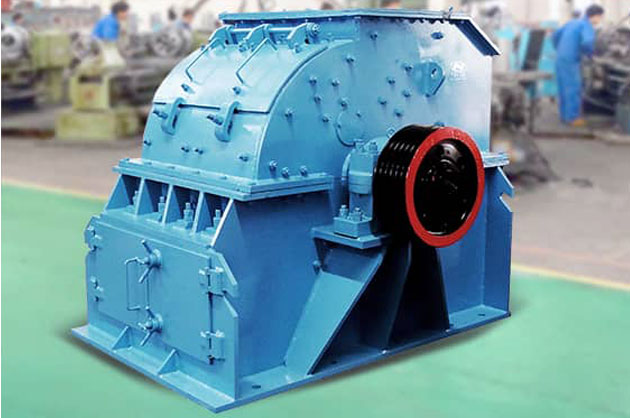

First, the equipment problems in normal operation of hammer crusher:

1)Spindle bearing position and bearing chamber wear;

2) The spindle roll key causes the key way to be damaged and the shaft to wear;

3) Wear of wheel shaft hole and key groove;

4) wear of ring hammer;

5) The bearing temperature is too high;

6) Other easy-to-impact scouring wear and so on.

In view of the equipment failure problem of hammer crusher, the general impact erosion problem and bearing damage are normal metal fatigue wear or due to inadequate maintenance. These problems are relatively simple to be solved by traditional technology and low cost.

The main shaft of the crusher is the most important part of the hammer crusher. Once the bearing position of the spindle is worn or worn with the belt wheel, it will seriously affect the operation of the whole equipment and bring a series of problems, such as serious vibration of the equipment, bearing damage and so on.

Second, the site repair program of hammer crusher broken bearing wear:

For the wear of the crusher main shaft, the traditional process repair scheme has the following categories:

1) On-site spot brush plating process

2) Overall disassemble, and then repair by repairing welding machine

3) Replacement of new parts.