Nowadays, machine-made sand is widely used in infrastructure construction. Sand washing is the last link of the sand production line. The main function of the sand washing machine is to clean sand, remove impurities and sludge quality. Sand washing machine generally has two kinds of spiral sand washing machine and bucket wheel sand washing machine, there is also called spiral classifier, is a kind of mineral processing equipment, it can also be used to wash sand. The spiral classifier is very similar to the spiral sand washing machine in appearance, and both have the function of sand washing. So, how should we distinguish?

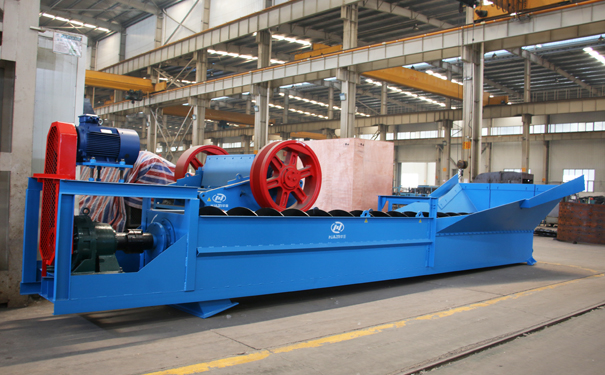

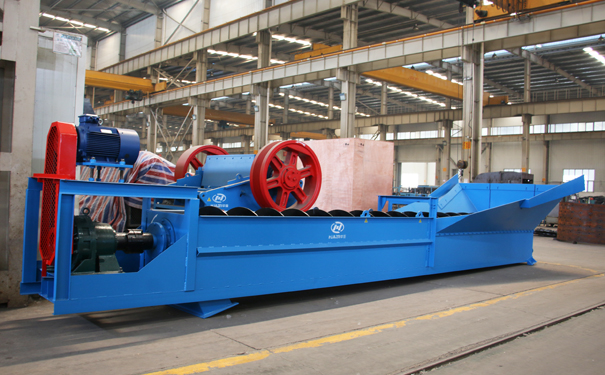

1. Equipment shape

The more obvious is the difference between the two blades. The blades of the spiral sand washing machine are solid blades, and the blades of the spiral classifier are hollow blades.

2. Working principle

The spiral sand washing machine needs to be arranged at an angle. The lower part of the water tank is surrounded by a three-sided weir plate to form a sedimentation tank. The spiral head is submerged in the sedimentation tank. Three functions: cleaning, dehydration and classification.

The screw classifier is based on the principle that the solid particles are different in size and specific gravity, so the settling speed in the liquid is different. Fine ore particles float in the water and overflow, and coarse ore particles sink to the bottom of the tank. It can filter the powder milled in the mill, and then screw the coarse material into the feed port of the mill using the spiral piece, and discharge the filtered fine material from the overflow pipe.

3. Equipment application

The spiral sand washer is mainly used for the cleaning of sand and gravel, and the wheel sand washer is also commonly used. The output of the spiral sand washer is related to its length and width. Spiral classifiers are widely used in beneficiation plants to be combined with ball mills to form closed-loop shunt ores, or used in gravity beneficiation plants to classify ore and fine mud, and to perform particle size classification of ore pulp in metal beneficiation processes, as well as dewatering in washing operations, mud, dehydration and other operations.

4. Equipment production capacity

In terms of sand washing operations, since the area of the blades of the spiral sand washing machine is larger, more sand and stone materials will be transported at the same time, and the processing capacity is about 2-3 times that of the classifier of the same size.

5. Equipment silo

For equipment with the same size of sand washing, the hopper of the sand washing machine will be larger than that of the classifier, and the sand precipitation time will be longer, so the washed sand will be cleaner.

6. Model classification

The spiral sand washer is divided into single spiral and double spiral, and the processing capacity can be increased by increasing the length of the sand washing machine or the double spiral side by side. Spiral classifiers are mainly high weir single spiral and double spiral, low weir single spiral and double spiral, submerged single spiral and double spiral, low weir type is rarely used, mainly high weir type and submerged type.