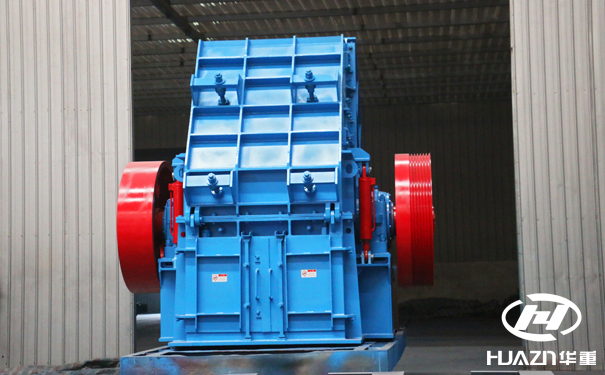

Hammer crusher is a crusher that is widely used in the mining industry. It is a kind of equipment that crushes materials in the form of impact. It can crush large materials into materials with the required particle size. Hammer crusher is suitable for crushing medium hardness materials in cement, chemical industry, electric power, metallurgy and other industrial sectors, such as limestone, slag, coke, coal and other medium and fine crushing operations. Some production enterprises that require high output per unit hour and do not have high requirements on ore hardness will prefer to use heavy hammer crushers. Materials such as limestone, which are not very hard, are very suitable for processing with a hammer crusher.

The hammer crusher mainly relies on impact energy to complete the crushing of materials. When the hammer crusher is working, the motor drives the rotor to rotate at high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head impacts, shears, and tears the material, causing the material to be crushed. At the same time, the gravity of the material itself causes the material to rush from the high-speed rotating hammer head to the baffle and screen strip in the frame. The output particle size is finally discharged outside the machine through the sieve plate.

1. Forming large and small materials at one time

Both large and small materials can be formed at one time, without the need for primary and secondary crushing, which enables low-cost operation, can reduce costs by about 40%, and has high output, reliable performance, and large processing capacity.

2. Wide range of applications

Heavy hammer crusher is widely used in mining, smelting, building materials and chemical, water conservancy and other industries, suitable for crushing limestone and medium hardness materials with compressive strength less than 250Mpa.

3. Low cost and low energy consumption

The heavy hammer crusher integrates the functions of coarse crushing and shaping when crushing stone, without going through the secondary crushing and shaping process, which can reduce the cost of equipment and energy consumption.

4. Safe and reliable operation

The large-diameter spindle and heavy-duty main frame make the equipment sturdy and durable, reliable in operation and the over-iron protection device and automatic control system can realize automatic safety protection.

5. Environmental protection and energy saving

The new heavy hammer crusher can spray water to reduce dust during the production process to reduce the pollution to the environment and is more environmentally friendly.

6. Compact structure and reasonable design

During the installation process, the machine is easy to operate, and the later maintenance is more time-saving and labor-saving.