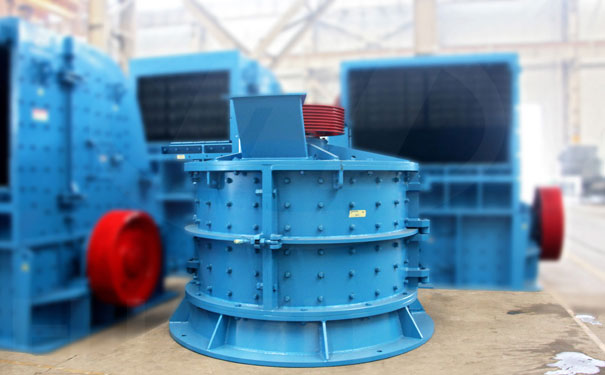

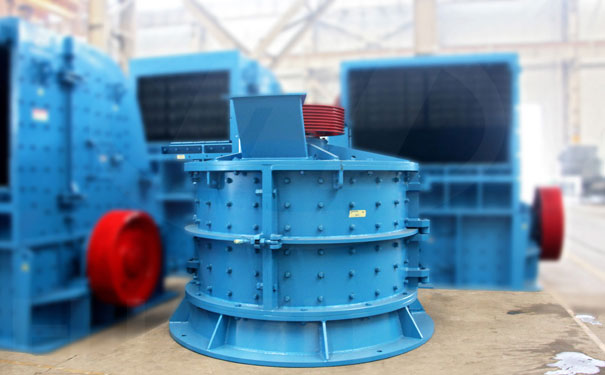

The PFL series vertical complex crusher is a new type of fine crushing and coarse grinding product developed by our company based on the technology of similar crushers at home and abroad, combined with the company’s many years of practical experience. The product has both impact and grinding crushing mechanisms. Our company presided over the drafting the national industry standard for this product. This series of products are widely used in the crushing operation of cement raw meal and clinker. It is an ideal fine crushing equipment for the technical transformation of cement plants to realize more crushing and less grinding, energy saving and consumption reduction. It is also suitable for the fine crushing and processing of various solvent raw materials in the iron and steel metallurgical industry. Crushing and processing of various medium-hard rock minerals in other construction, building materials, chemical and other fields.

Before understanding the compound crusher, we first give a brief introduction to its working principle. The rotor fixed on the main shaft is driven by the motor to rotate at a high speed in a certain direction when working. The bulk material falls from the feeding hopper to the spoiler. After the impact of the high-speed rotating spoiler, the centrifugal force down, was quickly thrown to the counterattack board and hit. Under the action of the inclined surface and gravity on the impact board, the material rebounds from the diagonally downward to the cone rotor crushing cavity. The materials is impacted by the high-speed rotating upper hammer, so that the material gains sufficient kinetic energy and then is thrown to the impact board, and repeat the above during the crushing process, the material groups collide with each other in the crushing cavity to be crushed again, and fall in a spiral line in the conical space. The material enters the cylindrical rotor cavity, and the crushed particles are further finely crushed, squeezed, and ground, and the above-mentioned crushing process is repeated again. Such high-frequency hits, counterattacks, squeezing, and grinding by the upper, middle, and lower hammerheads and counterattack plates make the material gradually broken from big to small. Because the material is impacted by the hammer head and the impact plate in the crushing cavity, and the material collides with each other, the material is broken along its natural joint surface and bedding surface. When the crushed material is smaller than the discharge gap of the upper rotor, the material enters the crushing cavity of the middle rotor for fine crushing. Then, the material enters the crushing cavity of the lower rotor, and the above-mentioned crushing process of striking, counterattack, squeezing and grinding occurs again. The difference is that the peripheral speed of the hammer head of the lower rotor is higher than that of the second stage, and the impact force of the material is more severe. Larger, smaller gap, so the material can be finely broken into smaller pieces, and finally broken into the required particles and discharged from the body.

From the perspective of crushing effect: the vertical complex crusher has a large crushing ratio, and there is no problem with the crushing of limestone. The output particle size can be adjusted arbitrarily, and it is not affected by the abrasion of the hammer and liner. Optional water-cooled chassis, high temperature resistant bearings and high temperature resistant high temperature grease above 260℃ can crush high temperature materials (material temperature below 150℃).

From the point of view of the equipment structure: the rotor body of the vertical complex crusher has a unique structure, forming a multi-stage continuous crushing cavity, and the energy and space are fully utilized to improve the performance of the machine. In addition, the spoiler ribs and the spoiler liner are distributed across the circumference, and the spoiler ribs can be used as the spoiler liner after they are worn, which improves the material utilization rate and reduces the use cost.

From the perspective of crushing benefits: the particle size of limestone crushed by the vertical complex crusher can also be used for the crushing of cement clinker in cement plants. It is also suitable for the fine crushing of various solvent raw materials in the iron and steel metallurgical industry and other construction, building materials. The crushing and processing of various medium-hard rock minerals in the chemical industry and other fields is widely used and can meet the various production needs of users.

From the perspective of environmental protection and energy saving: the use of high hardness and high toughness multi-alloy wear-resistant hammers and liners are resistant to wear and impact, longer service life, good equipment sealing performance, low dust, low noise, stable operation, and convenient operation and maintenance.