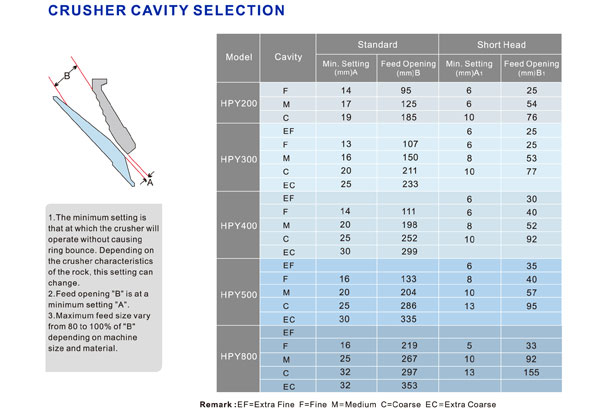

The HPY series multi-cylinder hydraulic cone crusher of Luoyang Dahua Heavy Industry has many models, which can meet different production requirements. For large, medium and small users, we can provide suitable machines on the basis of ensuring the output and crushing effect type. In order to meet the various needs of different users, the cavity types of HPY series multi-cylinder hydraulic cone crushers are mainly divided into EF (extra fine), F (fine), M (medium), C (coarse), EC (extra coarse). The model, let’s take a look at the detailed parameter table to have a preliminary understanding.

In the above parameter table, we see that each different model of multi-cylinder hydraulic cone crusher has a different cavity type, so how to choose the cavity type? Choosing the right cavity is undoubtedly also very critical for the production of sand and gravel, not only can improve the crushing efficiency, but also improve the quality of the output. So, how to choose the cavity type of the multi-cylinder hydraulic cone crusher?

1. According to the particle size and abrasiveness of the feed

The feed opening of the crusher should not be smaller than the maximum feed size. The feed inlet cannot be too large or too small.

If the inlet is too large:

The materials are mainly concentrated in the lower part of the crushing cavity, causing excessive wear of the lower part of the liner and low utilization rate of the liner.

If the inlet is too small:

①Materials cannot enter the crushing cavity, the production capacity is severely shrunk, and the inlet lining is severely worn or even destroyed.

②It causes large fluctuations in the crushing force and the jump of the adjustment ring, which causes damage to the frame seat gasket, accelerates the wear of the locking cylinder seal, and affects the stability of the equipment.

2. According to the output particle type and particle size

The product size depends on whether the crushing process is open-circuit crushing or closed-circuit crushing.

Generally speaking, the tight side discharge opening of the crusher is equal to the size of the screen hole or slightly larger than the average particle size of the required product. Each cavity type has a minimum discharge opening, and the minimum discharge opening should be avoided when choosing the cavity type.

Relatively small crushing cavity type can set a smaller discharge opening and better adjust the discharge opening. A small crushing cavity is easier to obtain a good grain shape. In terms of product size, the short-head type crushing cavity can obtain better product size, followed by the standard fine cavity type. In order to ensure a good product size, the crushing ratio should be controlled at 3 to 3.5.

The multi-cylinder hydraulic cone crusher needs a good crushing system plus the correct cavity type selection and standardized operation methods, which can exert the greater value of the multi-cylinder hydraulic cone crusher.