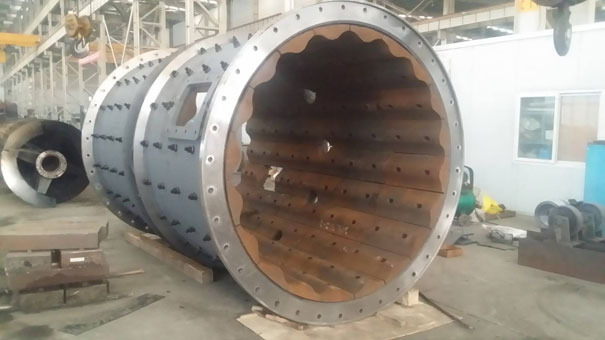

Maintenance and repair of ball mill

The maintenance and repair of the ball mill is a regular task. The quality of the repair work directly affects the operation rate and service life of the ball mill. Then how to maintain and repair the ball mill correctly during use is introduced as follows:

1. All lubricating oil should be discharged when the mill is put into continuous operation for one month, thoroughly cleaned, and replaced with new oil. The oil will be changed approximately every 6 months thereafter.

2. The lubrication condition and oil level of each lubrication point are checked at least every 4 hours.

3. When the mill is running, the temperature rise of the main bearing lubricating oil should not exceed 55°C.

4. When the mill is running normally, the temperature rise of the transmission bearing and the reducer should not exceed 55℃, and the maximum should not exceed 60℃.

5. The large and small gears drive smoothly without abnormal noise. If necessary, adjust the gap in time.

6. The ball mill runs smoothly without strong vibration.

7. There should be no abnormal fluctuations in the motor current.

8. There is no loosening of the connecting fasteners, any oil leakage, no water leakage, and no ore leakage on the joint surface.

9. The steel balls are added in time according to the wear condition.

10. If an abnormal situation is found, the grinding should be stopped immediately for maintenance.

11. The mill liner should be replaced when it is 70% worn or there are 70mm long cracks.

12. The liner bolts are damaged and the liner should be replaced when it becomes loose.

13. The main bearing should be replaced when it is severely worn.

14. The sub-board of the grid ball mill should be replaced when it is worn out and can no longer be repaired.

15. After the gear surface of the big gear is worn to a certain degree, it can be turned over and used again.

16. The pinion gear is severely worn and should be replaced.

17. When the incoming and outgoing material spiral is worn, it should be repaired by welding in time, and should be replaced when it is worn out to weld repair.

18. Loose or damaged foundation bolts should be repaired in time.

Problem handling of ball mill

The maintenance of the ball mill is a regular work, and the quality of the maintenance work directly affects the operation rate and service life of the ball mill. In order to find defects in time and eliminate hidden dangers to ensure the normal operation of the mill, in addition to daily maintenance, it is also necessary to stop the grinding regularly (recommended once a month) for important parts such as hollow shaft, main bearing, simplified, reducer, size, check the gears carefully and make detailed records. Properly deal with the defects according to their priorities and arrange mid-repair and overhaul plans.