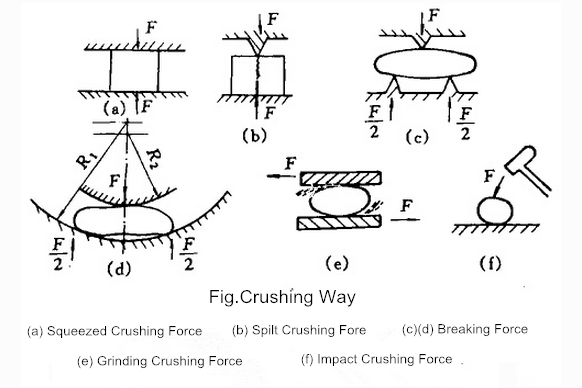

Mechanical Crushing utilizes external force that applied on the material, which overcomes the Molecular cohesion and breaks the large-block material into small pieces. Any crusher utilizes more than one force to break the material, usually with one main force and coordinates with other kinds of force. So the force that applied on the material by the crushing machine is complicated. The common force applied on the material are as below:

1. Squeezed Crushing Force

The mineral ore will be put between the crushing surfaces. A force (indicated as F demonstrated in below diagram) will be applied on the material, the material cannot bear its compressive strength and break down accordingly.

2. Spilt Crushing Fore

The mineral ore will be compressed between a surface and another one with sharp heaves (demonstrated as below diagram1). The ore will be split into halves towards the force, indicated as, applied direction. According to laboratory and theoretical analysis, the reason why the ores spilt into halves duo to the reason that, the force applied on the ors reaches the limit of ore’s compressive strength.

3. Breaking Force

The ore will be crushed between surfaces with sharp heaves or between two arc-shape surfaces. And then a force will be applied. The ores will be broken when the arc bending stress is over the ore’s compressive strength.

4. Grinding Crushing Force

Mineral ores undergoes the application of compressing force and cutting force at the same time. The cohesion within the ores reaches the limit of ore’s compressive strength and then break down.

5. Impact Crushing Force

The mineral ore breaks by receiving strong impact force given by high-speed rotating component. Since the force given in very short time, the deformation part cannot extend to the impacted place in time then generates tremendous local stress, which along the direction of the cracks breaking the material. Hence, the live load is much stronger than the still load.