Nowadays, mining machinery industry is booming, huge of crushing equipment is born: impact crusher, jaw crusher, cone crusher, PLS crusher and so on. Although there is similar crushing function, but the production capacity, feeding size is also different. How to select the crusher machinery to crush the different material becomes an important question.

Granite is hardness, the color of granite is beautiful and lasting, belongs to the first-class building materials. It is widely used in metallurgy, cement, thermal power, defense facilities and other fields. Therefore, the market prospect of processing and crushing granite is huge. But if the selection of production line is wrong, it can’t realize the profit maximization.

The traditional granite crusher is generally use jaw crusher and impact crusher. But granite is hard broken, it often cause serious wear to the hammer of impact crusher, and increase the cost of production.

(1) If the requirement of stone grain shape is not high, the jaw crusher and cone crusher are the main equipment to realize the two-stage crushing, this preparation can reduce the consumption rate of parts in the production.

(2) If the customers have higher requirement on stone grain shape, add a PLS crusher to crush stone, finally it can produce the cubic artificial sand.

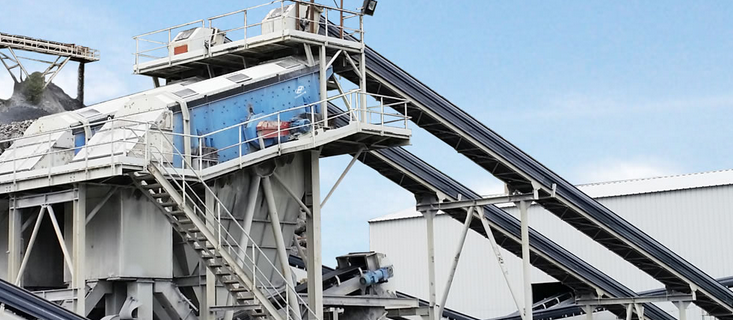

The granite production line equipment of HUAZN, crushing equipment at different levels is reasonable matching, spatial layout is strict. The whole process is discharging smooth, reliable operation, convenient operation, high efficiency and energy saving. Provide the full-service of pre-sale, sale and after-sale, according to the production site of customer to dispose the process to achieve the most reasonable, the most economical product line for customer.