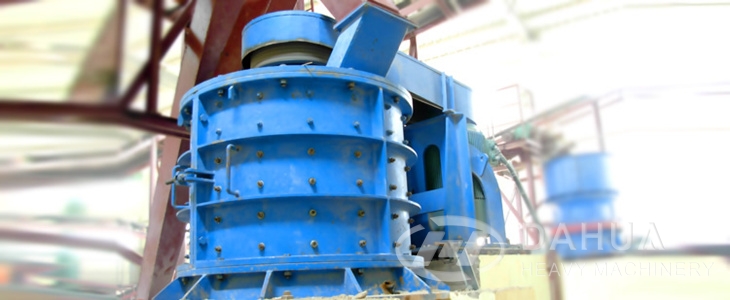

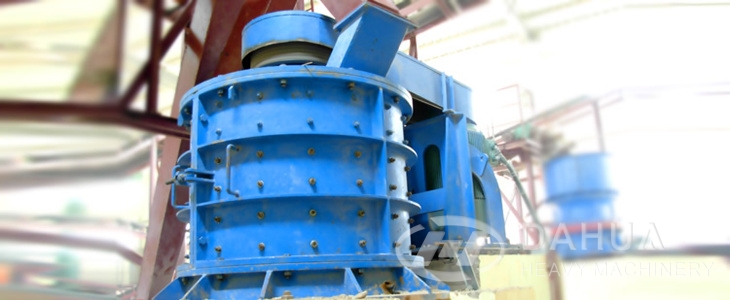

Complex vertical crusher is widely applied in the fields of mining, construction, cement, chemical industry and metallurgy etc. Normally we may encounter some problems in the production, Luoyang Dahua with several decades of manufacturing crushing machine summarizes some solution for the customer.

I. Noise fault

During the running, there are very violent knocking sounds occured inside the crushing chamber of complex crusher. First of all, the crusher power must be switched off, then stop and clean the crushing chamber; Secondly, the machine will produce a great vibration in the operation process, check whether the materials cannot be broken entered into the crushing chamber; Then check the plates fastening condition and the clearance between hammers and liners, confirm whether wear-resistant liners fall off.

II. Granularity question

The particle size is too big during the discharging of complex crusher. First of all, should adjust the clearance between front and rear impact plates or replace worn liner plates and flat hammers; Moreover, should adjust the position of impact frame to achieve relative clearance between its both sides and frame liner to ensure that the material granularity.

III. Bearing fault

Due to complex crusher operated for a long time under this harsh conditions such as large impact load, high vibration, high speed and more dusty, which aggravate the rotor bearing wear and effects the production running smoothly.

1. The bearing damage is mainly caused by the rotor or bearing installation unbalanced, the bearing seals aging, the worn entering into ash powder, the local stress in the process of rotor running with high speed and the insufficient bearing lubrication. Restricted by working environment and working ways, required the rules matching coefficient; should notice the balance installation of the rotor when installation, generally adopting the bearings with strong load capacity and good self-aligning performance as the rotor bearing. It is advisable for bearings selection to calculate the service life shall be at 5000-10000h.

2. Over heating of bearing. It is mainly caused by lacking of lubrication oil, or more oil, dirty oil and bearing damage. Firstly, should check whether the lubrication oil is sufficient or not, and add oil regularly, generally speaking, the volume of lubrication oil should be 50% of the whole bearing base. Secondly, pay attention to bearing daily cleaning and maintenance. Replace bearing if seriously damaged.

IV. Hammer head fault

Hammer head is the easy wearing part of complex crushing machine, which working surface will be damaged after long time working. The clearance ( below 10mm) between hammer head and liner plate increases, the mutual friction greatly decreases, which are the main reasons to cause hammer head abrasion.

1. To prevent foreign matters like metal hard block enter into crusher to damage hammer head or liner plate.

2. Adopt wear resistance material like high carbon manganese alloy cast steel or imbedding white iron to make hammer head to improve wearing coefficient, reduce change time.

3. Replace or repair hammer head if seriously worn out to ensure normal working.

V. Belt fault

There are many reasons to cause belt burning. For example, the belt may burn caused by heat and long time's wear; the belt tightness is not in the optimize position, the friction can lead to burn; machine blockage caused by overload may cause belt slipping.

First, should regularly check belt usage condition, adjusting its tightness by screw if found loose. Then, add ventilating device to improve heat dissipation of belt and motor.