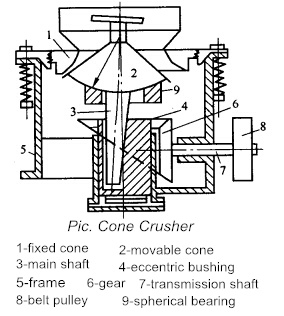

The working principle of medium and fine cone crusher is basically similar to that of gyratory crusher, but still have differences in the structure, the main difference (pic. ) is:

(1) The two cone shapes of gyratory crusher are steeply inclined, but the movable cone is erected and fixed cone is inverted truncated cone, which is mainly to increase the feeding needs. The two cone shapes of medium and fine cone crusher are slowly inclined and erected truncated cone, and also have a certain length of parallel mining area (parallel zone) between two cone, which is in order to control the discharge size requirements, because the medium and fine crusher is different from primary crusher, which takes crushed product quality and production capacity as the primary consideration factors.

(2) The movable cone of gyratory crusher hanging on the beam of upper part of machine; the movable cone of medium and fine cone crusher is supported on the spherical bearing.

(3) The gyratory crusher adopts the dry dust device; the medium and fine cone crusher adopts the water seal dust device.

(4) The gyratory crusher was used to adjust the rising or falling of movable cone to change the discharge opening size; the medium and fine cone crusher is used to adjust the height of the fixed cone (adjusting ring) to realize the width adjustment of discharge opening.

According to different adjusting device of discharge opening and the methods of insurance, the medium and fine cone crusher is divided into the spring cone crusher and hydraulic cone crusher.