Jaw crusher firstly appeared at 1858, it was a kind of squeezing crushing machine. Its main components are fixed jaw plate, movable jaw plate, eccentric rotating wheel, and crushing cavity that composed of fixed law plate and movable jaw plate. Even jaw crusher is an ancient crushing machine, for its simple structure, reliable operation, easy manufacture and maintenance, it is widely used in many fields. Especially in disposing solid waste, jaw crusher is used for crushing high strength and toughness, and strong corrosivity wastes.

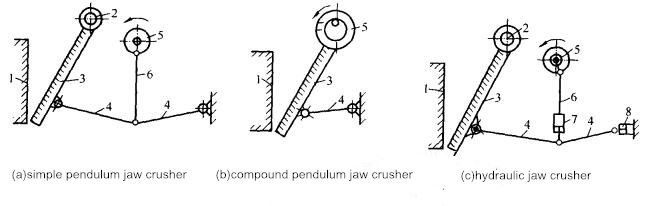

According to the motion characteristic of jaw plate, it can be divided into simple pendulum jaw crusher and compound pendulum jaw crusher. In recent years, hydraulic technology is applied in crushing machine, the hydraulic jaw crusher appeared on the market. See figure 1 – Main type of jaw crusher.

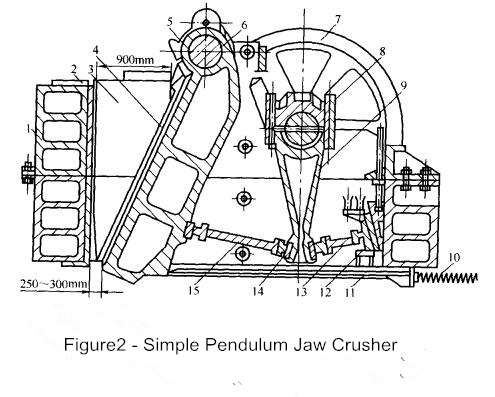

1. Simple Pendulum Jaw Crusher

Figure 2 is shown the structure of simple pendulum jaw crusher. This crusher is composed of frame, working mechanism, transmission mechanism, and safety device, etc. The bottom fixed jaw and movable jaw form the crushing cavity. The fed materials are squeezing, breaking and bending by the reciprocating moved movable jaw that rotated by the eccentric shaft. When the movable jaw leaves the fixed jaw, the crushed materials at the bottom of the crushing cavity that smaller than the discharge opening are discharged through its own gravity, the large parts at the top of the crushing cavity falling down for further crushing.

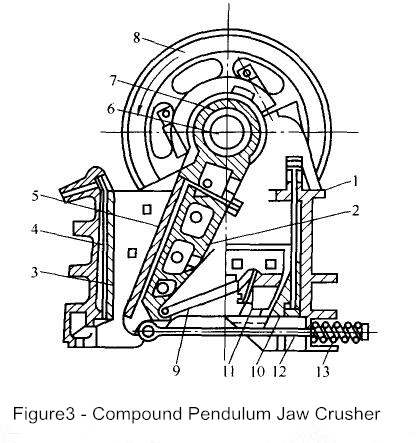

2. Compound Pendulum Jaw Crusher

Figure 3 is shown the structure of compound pendulum jaw crusher. Seen from the structure, the compound pendulum jaw crusher hasn't a mandrel compared with simple pendulum jaw crusher. Its movable jaw connects with connecting rod as a whole part, no vertical connecting rod, and only has one piece of axillare. So the structure of compound pendulum jaw crusher is simpler, but the movement of movable jaw is more complex than that of simple pendulum jaw crusher. The movable jaw moves both vertically and horizontally, in this way, it calls compound pendulum jaw crusher.

The grain size of compound pendulum jaw crusher is finer, the crushing ratio is large, and the stroke of the top of movable jaw is large which can meet the required crushing load. The downward movement of movable jaw can promote discharging, so the productivity is higher 20%-30% than the simple pendulum jaw crusher with the same specification. But the large stroke of movable jaw quickens the abrasion of jaw plate.