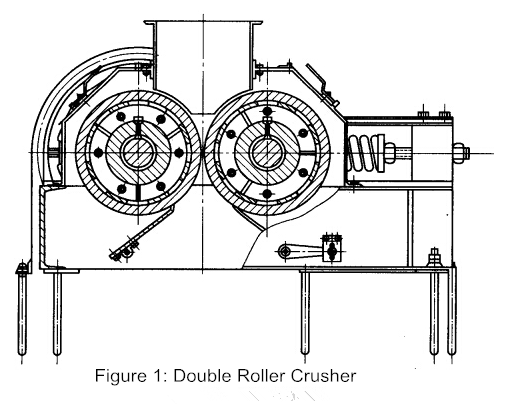

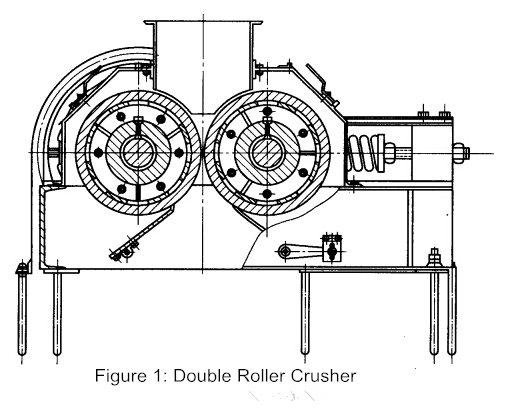

The main components of double roller crusher are crushing roller, the spring safety device, adjusting device, transmission device and frame, etc. Figure 1 shows the structure diagram of double roller crusher (smooth surface).

Crushing roller: Two opposite rotary rollers that parallel fixed on the horizontal shaft, which is an important part of the crusher. One of the roller bearing is moving, the other one is fixed. The crushing roller is composed of main shaft, wheel hub and roll skin. The roller shaft adopts the key cooperate together with wheel hub of conical surface, the roller skin fixed on the wheel hub, with three pieces of taper arc iron and fixed together with bolts and nuts. Because the roller skin directly contact with minerals, the skin need to be replaced sometimes and is commonly used to be produced by better wearability high manganese steel or special carbon steel(chromium steel, chromium-manganese steel, etc.).

Spring safety device: It is a very important component for the roller crusher. The spring tightness has a very important role for normal work and overload protection of crusher. When the machine works properly, the pressure of the spring should be able to balance the forces between the two rollers, to keep the clearance of discharge opening, make the product granularity evenly. When the unbroken objects enter into the crusher, the spring should be compressed to force the movable crushing roller horizontal movement, then the width of discharge opening increasing, ensure the machine is not damaged. After the unbroken objects discharged, spring is restorable and the machine work as usual. During the machine operation, insurance spring is always kept in a state of vibration, so the spring easy to be damaged. Should regular inspection and replaced regularly.

Adjusting Device: It is used to adjust the gap (discharge opening) between two rollers by adding washer between roller bearings or using worm gear adjusting device.

Transmission device: Electric motor drives two rollers making opposite rotational movement through V belt (or gear reducer) and a pair of long toothed gear. When the unbroken materials enter into crusher, the distance between two rollers change, and the long toothed gear remain engaged. Long toothed gear transmission device used in double roller crusher with low RPM and the peripheral speed of roller surface smaller than 3m/s. For the high RPM crusher (peripheral speed large than 4m/s), adopting separate motors to drive rollers, so the total price is high for installing two motors.

Frame: It is made of casting iron or welded or riveted by section steel with strong structure.