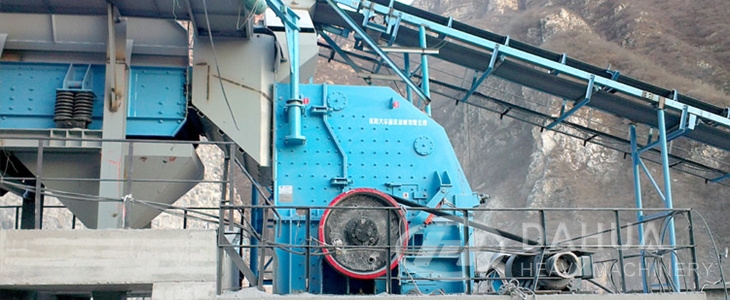

Impact crusher is the common crushing equipment in sand production line and crushing production line. Good maintenance can ensure the impact crusher working stably. Today, Luoyang Dahua will share the right maintenance of impact crusher.

1. Each shift must fully check the machine after completion of the work.

2. Each week to take a complete inspection for the motor and lubrication system, checking fastener situation, belt drive, bearing seal, impact liner plate and its abrasion etc.

3. Adjust the clearance between rotor and impact plate. Do not adjust when the rotor is running. If the materials are left between impact plate and shell, before adjust the clearance, lift the impact frame, the materials become loose that is easy to adjust.

4. Replace wearing parts. Open the back of top frame, loose the connecting bolt of back of top frame and the box, and then open the top frame slowly.

5. Plate hammer. Should timely adjust ore replace plate hammer when it wear in a certain degree to prevent fastening and other components are damaged.

6. Liner plate. Open the back of top frame, remove the split pin, slotted nut, bolt that used to fix the liner plate, in this way, we can change the worn plate. If you install the new liner plate, reverse the above step.

7. Bearing. If the bearing temperature is too high, it is due to more of lack of lubrication oil, dirty grease, or bearing damaged. It is the key step in sand production line.

Luoyang Dahua reminds the customer make sufficient maintenance and repair to ensure the long-term stable operation.