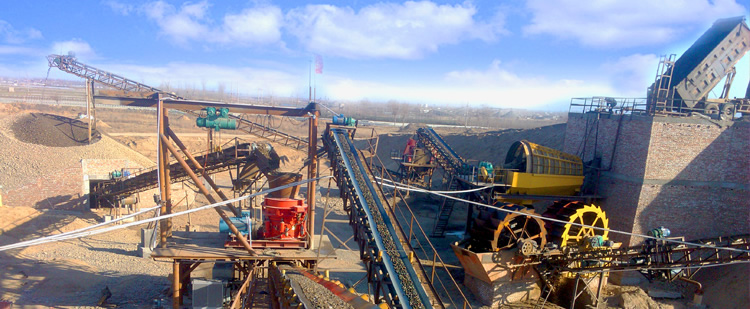

The ore are crushed by jaw crusher, hammer crusher,cone crusher,impact crusher and other types of crushing machine. It aims to make the final products meet the requirement of granularity,shape and other aspects. Normally,the performance of the crushing production line is evaluated from the aspects of cruhsing efficiency,output,product granularity,etc. Which factor will affect these evaluate standards?

There are many factors to affect the crushing production. Today, let's talk about the two main factors. One is from the ore property,another is operation procedure.

1. Ore property

1) Ore hardness. The ore is more hard,the compressive strength is bigger,and more hard to crush,resulting in low production capacity,and vise versa.

2) Feed size. If there are more large block of ore in the feed materials,it will cause coarse average grain size,heavy workload and low production capacity.

3) Content of adhesive material in ore. When content more silt or ore fines,this fine particles will adhere to the coarse ore,thus greatly reduce the discharg speed, even stop the crushing operation.

2. Operation procedure

The operation procedure of crusher also affect its production capacity. Continuous and even feed is the precondition of normal running. Add more cycle load in closed circuit crushing can make feed granularity become fine,and can achieve qualified intermediate products together with crushing. Therefore,the operation should take place under the condition of big crushing ratio,high load factor in closed circuit. As a result,the crushing ratio can be improved by complying with right operation sequence,and constantly optimizing operation process.