800 TPH Granite Crushing Process

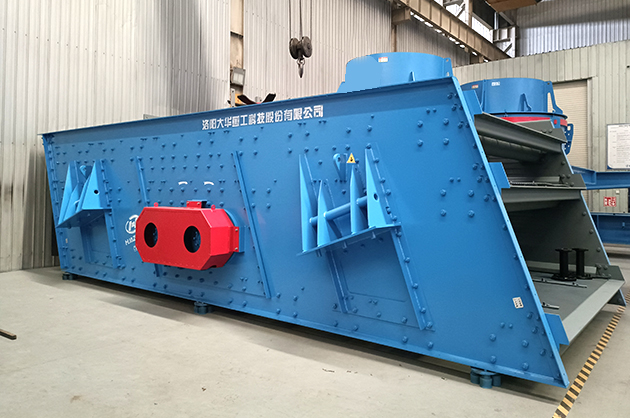

The granite crushing production line primarily consists of four processes: feeding, crushing, sand making, and screening. It is typically composed of vibrating feeder, jaw crusher, cone crusher, vibrating screen, sand making machine, sand washing machine, belt conveyor system, centralized electric control panel and other necessary equipment. The granite crushing production line designed by Luoyang Dahua has an output range of 60-1000 t/h, making it suitable for applications in mining, hydropower, high-speed railway construction, building materials, highways, and urban construction.

Granite Crushing Production Line Advantages

High degree of automation; Reasonable configuration,

Low operation cost

High crushing rate, Energy saving

Large output, less pollution

Easy maintenance

Uniform particle size,

Good particle shape,

Reasonable gradation

Working Principle

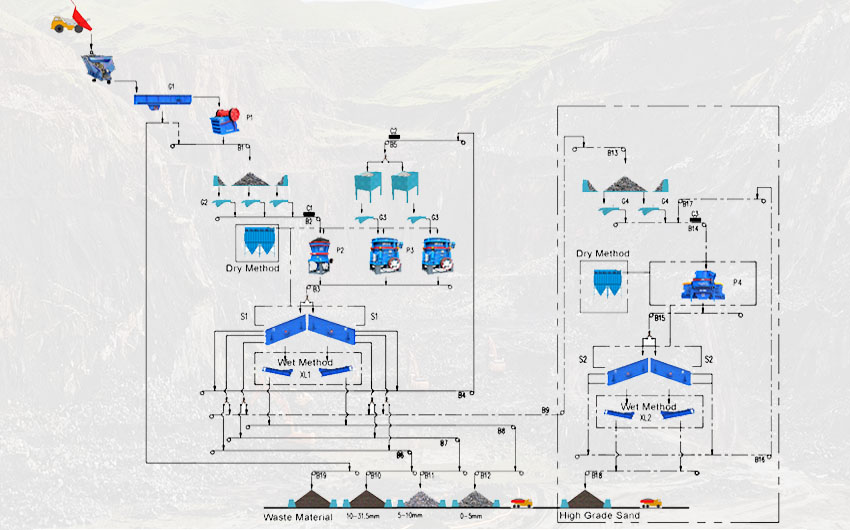

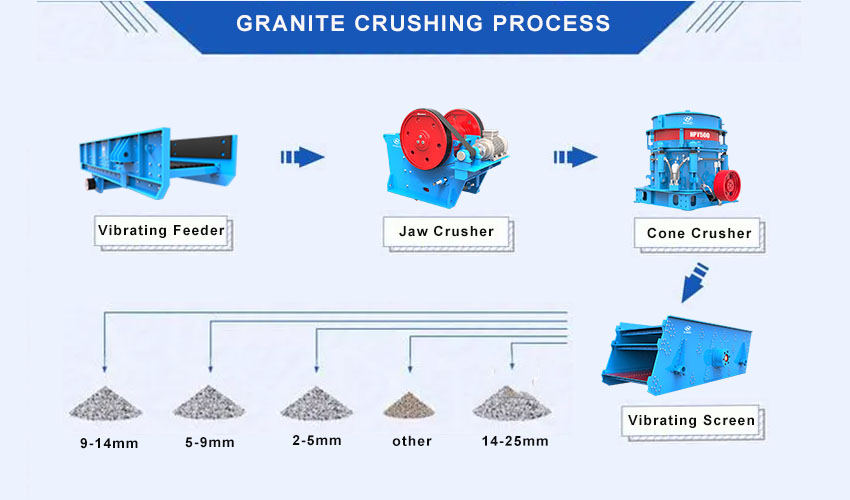

The stone material is uniformly fed into the jaw crusher for coarse crushing by the vibrating feeder, and then the coarsely crushed material is sent to the granite cone crusher for secondary crushing. Subsequently, the crushed material is conveyed to the vibrating screen via the belt conveyor for screening. The stones that meet the feeding requirements of the sand making machine are directed to it for further processing, while those that fail to meet such requirements are returned to the cone crusher for re-crushing before being re-screened on the vibrating screen. The qualified sand particles are sieved into a sand washing machine for cleaning and subsequently transported as finished products through a belt conveyor. Any mixed materials of sand and stone that do not meet quality standards will be sent back to undergo re-crushing in the sand making machine.

The stone materials are uniformly fed into the jaw crusher for coarse crushing, and then the coarsely crushed materials are sent to the granite cone crusher for secondary crushing. Subsequently, the stones that meet the feeding requirements of the sand making machine are directed to it for further processing, while those that fail to meet such requirements are returned to the cone crusher for re-crushing. The qualified sand particles are sieved into a sand washing machine for cleaning and subsequently transported as finished products.

800TPH Granite Crushing Process

1Feeding process: The vibrating feeder is commonly utilized in the industry at present, facilitating the even and continuous transportation of stones from the raw material bin to the primary crushing equipment. This process is stable and reliable.

2Crushing process: The crushing operation in this process is divided into coarse crushing and medium-fine crushing. Coarse crushing is achieved with a jaw crusher, while impact crusher and cone crusher are primarily used for medium-fine crushing.

3Sand making process: The medium and fine crushed materials that meet the requirements are sent to the sand making machine for sand making and shaping. The unqualified stones are returned for re-crushing.

4Screening process: The crushed and sand-made stone requires screening to effectively regulate the size of the final product and segregate sand and stones that cater to different industries’ needs.

5Conveying process: The belt conveyor is an indispensable piece of equipment in the granite crushing production line as it runs throughout the entire process, facilitating material conveying in each stage.