Basalt Crushing Production Line

Processed material: granite, pebble, orthoclase, gabbro, diabase, peridotite, andesite, and rhyolite, etc.

Crushing process: 3 stage crushing process. Coarse crushing + medium crushing + fine crushing / sand making

Basalt crusher: jaw crusher, cone crusher/impact crusher, sand making machine, sand washing machine

Basalt Crushing Production Line Introduction

The basalt crushing production line is applied for the hard stone crushing which is designed by Luoyang Dahua. The production line has the features of high automation, high crushing ratio, low operation cost, energy saving and fine granularity. According to the specific production requirements, the company can offer you the comprehensive production line solution and technical support to meet your demands.

The basalt crushing production line is applied for the hard stone crushing. The whole production line has the features of high automation, high crushing ratio, low operation cost, energy saving and fine granularity. Luoyang Dahua can offer you the comprehensive production line solution and technical support to meet your demands.

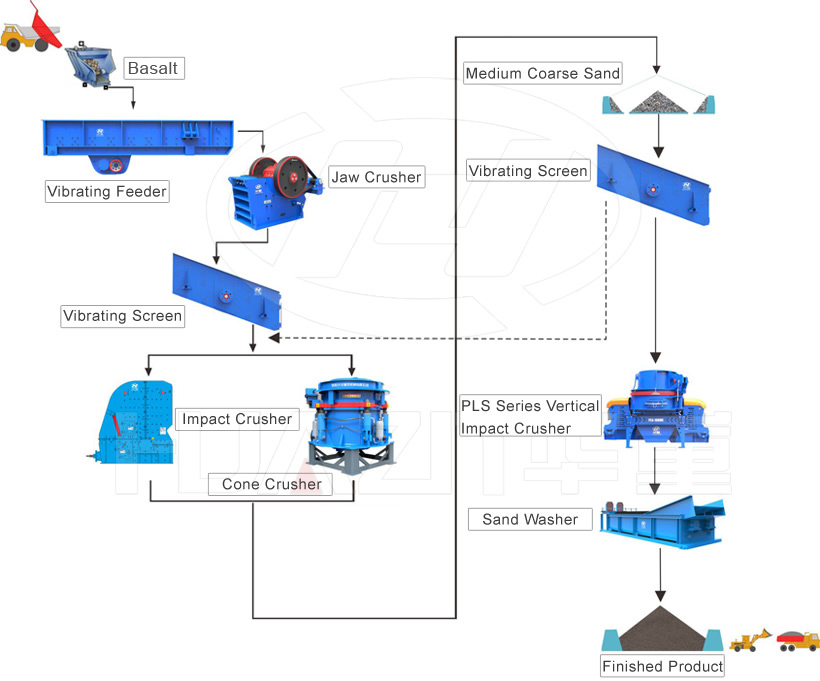

Basalt Crushing Production Line Process

The basalt crushing production line capacity is 30-700 t/h, which contains three procedures, namely, coarse crushing by jaw crusher, medium crushing by impact crusher and fine or re-shape by cone crusher.

※ Feeding: vibrating feeder.

※ Coarse crushing: jaw crusher with feed size of 1500-500mm, crushing to 400-125mm.

※ Medium crushing: cone crusher or fine jaw crusher with feed size of 400-125mm and crushing to 100-50mm.

※ Fine crushing: impact crusher (or sand making machine), feeding particle size of 100-50mm, crushing to 32-5mm.

※ Screening + dedusting: vibrating screen + dry deduster.

Related Products

Max. Feed Size: 720-1360 mm

Production Capacity: 55-1500 t/h

Max. Feed Size: 35 – 560 mm

Production Capacity: 45-1200 t/h

CSS: 6 – 51 mm

Production Capacity: 60-2500 t/h

Max. Feed Size: 30-60 mm

Processing Capacity: 24-715 t/h