The impact crusher is a type of processing equipment that utilizes impacting force to break hard and brittle materials. Due to its excellent particle shape and high fineness, it is often compared with gravel sand making machines in stone production lines. Can impact crusher be used for sand making? Which type of sand making machinery is better?

Can Impact Crusher be used for Sand Making?

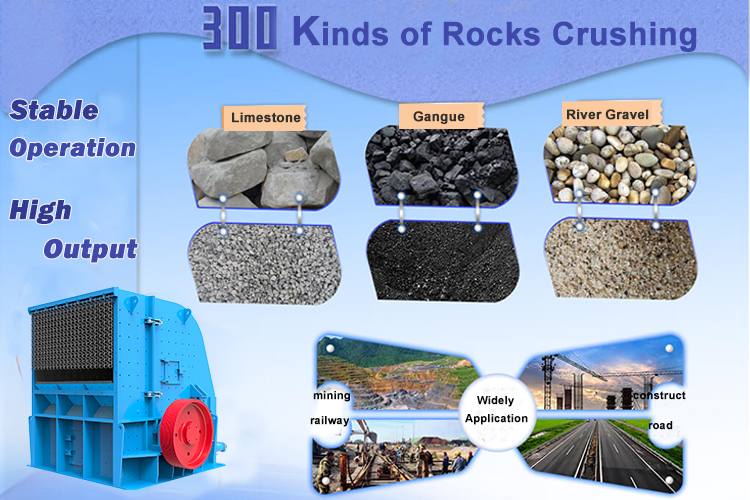

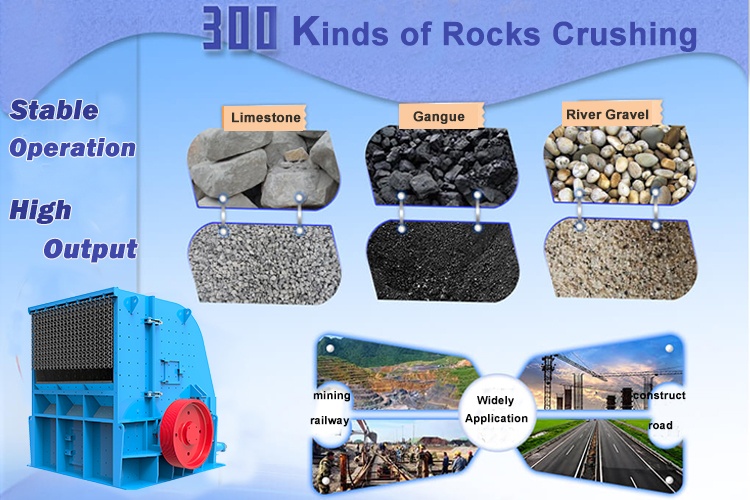

Yes. The impact crusher, as a medium and fine crushing equipment, is capable of crushing stones from 30-40 cm to less than 5 cm. Moreover, it can also achieve particle sizes below 5mm. Therefore, in terms of particle size reduction, the impact crusher can make sand.

Impact crusher advantages for sand making:

1. The gap between the impact plate and the plate hammer can be easily adjusted, allowing for effective control of the particle size during discharge and resulting in a favorable particle shape.

2. The equipment has excellent adaptability and can effectively crush mine stones with low hardness, brittleness, toughness, and water content. The crushed product is characterized by a uniform particle size and a cubic shape.

3. The rotor structure is robust, enhancing both the throughput and crushing ratio. The high chromium plate hammer possesses impact resistance, wear resistance, and other outstanding characteristics.

4. The price of impact breaking is cheap, with micro-shaping and crushing effect, and the processed material has uniform particle size.

Impact crusher disadvantages for sand making:

1. The plate hammer and impact plate will wear out too quickly if high hardness mining materials are not handled properly, leading to frequent replacement of parts. This will increase production costs and cause delays in production time.

2. The sand produced by impact crusher may contain a higher amount of powder compared to professional sand making machines, and it still falls short in meeting the more stringent requirements for sand grain type.

Which sand making machinery is better?

The impact crusher offers certain advantages in the process of sand production in stone plants; however, it does have some limitations. Therefore, which type of sand making machine equipment is more suitable for stone factory operations? The vertical shaft sand making machine is recommended here!

1, Deep cavity impeller, pass capacity is increased by 30%.

2, The upper and lower protection plate can be turned to extend the service life.

3, Combined throwing head, only need to replace the wear part, can reduce the use cost by 30%.

4, Center and surrounding feed, flexible adjustment, easy to transform.

Therefore, whether in terms of output, service life, or cost reduction, the vertical shaft sand making machine has unparalleled advantages, and this equipment can be broken, but also shaped, simple maintenance, easy to use, in many sand factories can see its figure.

Of course, the selection of sand making machine should consider various factors such as the type of raw material, capacity requirements, finished product specifications, budget constraints, and maintenance costs. The ultimate objective is to enhance production efficiency while ensuring product quality and supporting the sustainable development of the stone factory.