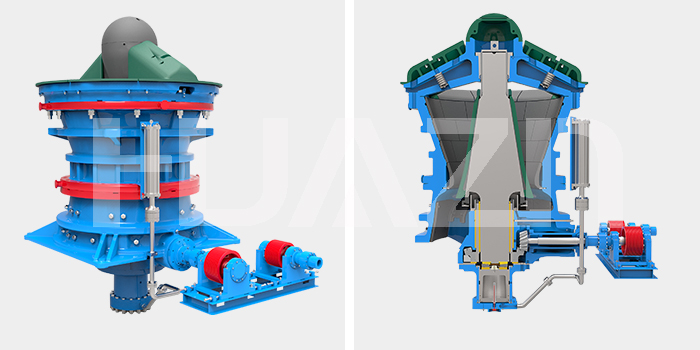

The gyratory crusher is a type of cone crusher, serving as a coarse crushing machine. This crusher has high productivity, low power consumption, and smooth operation, which is suitable for crushing sheet materials. The disadvantage of the gyratory crusher is that the structure is complex, the price is higher, maintenance is more difficult, and repair costs are large. Additionally, the high fuselage increases the cost of building and foundation structures.

The gyratory crusher is suitable for application in factories and mining yards with high production capacities. According to the experience, if the production requirements can be met by a jaw crusher alone, then it should be used; If two types of jaw crushers are required, a gyratory crusher should be considered.

Working features of gyratory crusher

(1) Simple and reasonable structure, low operating cost. The utilization of the stone beat stone crushing principle results in minimal wear.

(2) High crushing rate, energy saving.

(3) With fine crushing, coarse grinding functions.

(4) The water content of the material is little affected, and the water content can reach about 8%.

(5) The working noise is less than 75 decibels (db level), and the dust pollution is less.

(6) Suitable for crushing medium hard and extra hard materials.

(7) The product is cubic, the accumulation density is large, and the iron pollution is minimal.

(8) Impeller self-lining wear is small, easy maintenance.

Luoyang Dahua gyratory crusher parameter

Parameter

| Model |

Feed Opening (mm) |

Rotate Speed (rpm) |

Power (kw) |

CSS(mm) / Throughput Capacity(t/h) | ||||||||||

| 125mm | 140mm | 150mm | 165mm | 175mm | 190mm | 200mm | 215mm | 230mm | 240mm | 250mm | ||||

| GC42-65 | 1065 | 600 | 375 | 2000 | 2320 | 2500 | 2860 | |||||||

| GC50-65 | 1270 | 600 | 375 | 2380 | 2770 | 2920 | ||||||||

| GC54-75 | 1370 | 600 | 450 | 2870 | 2970 | 3130 | 3320 | 3470 | ||||||

| GC62-75 | 1575 | 600 | 450 | 2880 | 3600 | 3810 | 4200 | 4220 | ||||||

| GC60-89 | 1525 | 600 | 600 | 4180 | 4530 | 5070 | 5280 | 5520 | 5800 | |||||

| GC60-110 | 1525 | 600 | 1200 | 5520 | 6930 | 7320 | 7560 | 8270 | 8580 | 8880 | ||||

Remark: The above capacities are based on an assumed feed where 100% of the feed passes 80% of the feed opening. 80% of the feed passes 50% of the feed opening, and 30% of the feed passes a sieve size that is 10% the feed opening. The capacities are for feed materials with a bulk density of 1.6t/m³. All capacities are calculated at a maximum throw for respective machine.