Basalt has the advantages of good corrosion resistance, high hardness, high compressive and flexural strength, high temperature resistance and hydration resistance. The sand aggregate produced after crushing and processing can be used in various fields such as building masonry, concrete mixtures, asphalt mixtures, etc. It is a high-quality construction material, which is why more and more customers are investing in basalt sand production plants. Therefore, what crusher equipment configuration is required for a complete basalt sand production line? And how much does it cost?

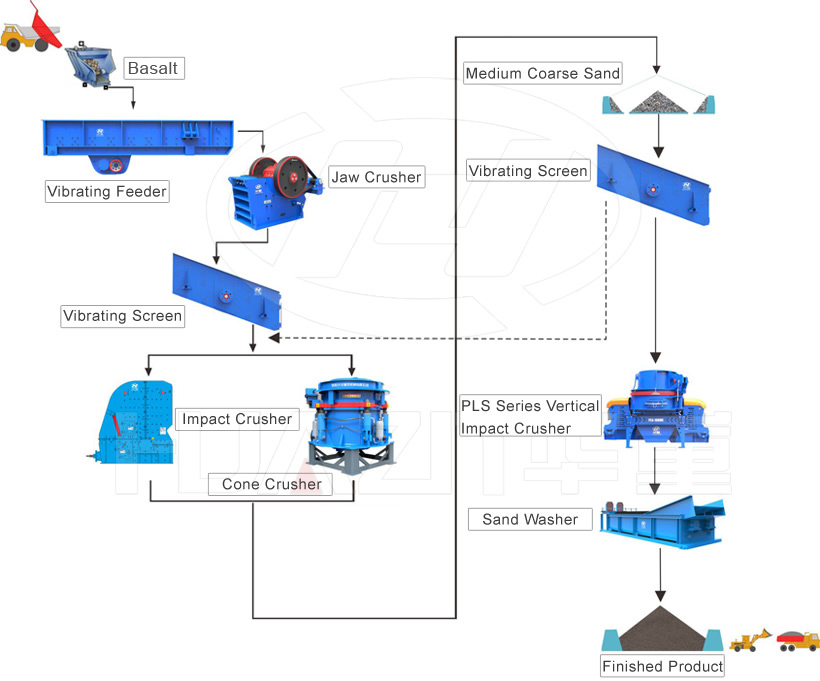

Typically, the basalt sand production lines are equipped with jaw crushers, cone crushers, impact sand making machines, and auxiliary equipment such as vibrating screens, feeders, and conveyors.

Coarse crusher: The JC jaw crusher is commonly employed for primary basalt crushing, specifically designed to handle large stones and facilitate subsequent processing.

Medium crusher: Due to the hardness of basalt, GPY single-cylinder hydraulic cone crusher is an optimal choice for the medium crushing stage, enabling efficient processing and achieving superior particle size distribution while reducing costs.

Sand making machine: The sand making machine serves as the pivotal equipment in the sand production line. PLS vertical impact sand making machine is commonly employed for processing basalt, enabling efficient shaping and manufacturing of high-quality sand and stone products.

Sand washing machine: The DXS wheel sand washing machine is commonly utilized to enhance the purity and quality of sand and stone aggregate, effectively eliminating stone powder and debris contaminants from the sand, thereby enhancing its overall quality.

The integration of these devices facilitates the efficient processing of basalt into high-quality sand and gravel products, catering to diverse application fields.

The price of a set of basalt sand making equipment varies based on the configuration and manufacturers. To determine the specific price, it is recommended to consider production demand, equipment model, and configuration scheme before contacting the manufacturer for detailed consultation.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.