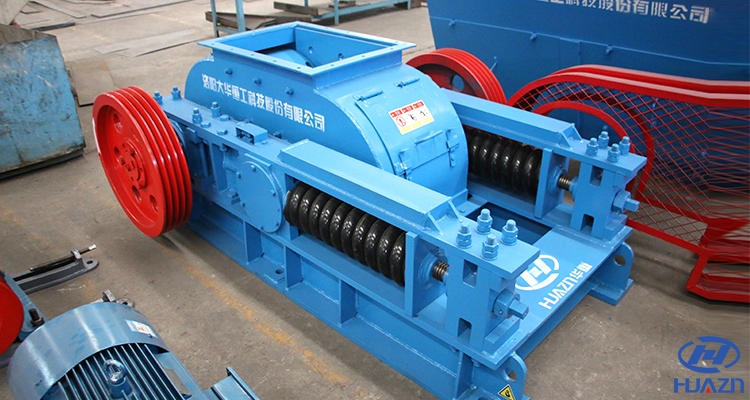

Hydraulic roller crusher is an innovative device designed with advanced technology. This machine can effectively crush materials with various hardness in industries such as mineral processing, chemical, refractory, stone, and building materials. Moreover, it has the capability to produce both stones and sand. In this text, we will provide detailed information about its model, parameters, working principle, and general introduction.

Hydraulic roller crusher model and parameter

The output of the hydraulic roller crusher ranges from 3-450 t/h. It has 3 types, double roller crusher, 4PG Roller Crusher and 2PGC Roller Crusher. Each size corresponds to a different output capacity. The specific model and parameters of the hydraulic roll crusher can be chosen reasonably based on factors such as raw material processing, output, and demand for finished products.

| Type | Model | Feed Size(mm) | Discharge Size(mm) | Capacity(m3/h) | Power | Dimension(mm) | Weight(kg) |

| Strong Double Roller Crusher | 2PGQ 610×400 | <36 | 2-9 | 3-9 | 15×2 | 2085×3090×802 | 4130 |

| 2PGQ 750×500 | <40 | 2-10 | 3-16 | 18.5×2 | 2344×1900×1605 | 9600 | |

| 2PGQ 750×700 | <40 | 2-10 | 5-25 | 22×2 | 2344×2318×1605 | 10650 | |

| 2PGQ 900×500 | <40 | 2-10 | 5-26 | 22×2 | 2750×1956×1662 | 15000 | |

| 2PGQ 900×900 | <40 | 2-10 | 11-45 | ~37×2 | 2750×2356×1662 | 16800 | |

| 2PGQ 900×1200 | <40 | 3-10 | 15-60 | ~55×2 | 2750×2480×2065 | 20800 | |

| 2PGY 1200×1000 | <40 | 3-12 | 15-60 | ~45×2 | 3476×2894×2200 | 39000 | |

| 2PGY 1200×1200 | <40 | 2-12 | 18-68 | ~75×2 | 3476×3117×2200 | 41980 | |

| 4PG Roller Crusher | 4PG750×500 | <30 | 2-4 | 3-10 | 18.5+11/17 | 2760×2105×2650 | 19200 |

| 4PG900×700 | 40-100 | 2-10 | 11-18 | 30+15/24 | 3150×2450×2747 | 28488 | |

| 4PG900×900 | 40-100 | 2-10 | 14-24 | 45+24/37 | 3160×2650×2747 | 29140 | |

| 4PGY1200×1000 | 20-40 | 3-10 | 43-68 | 90+40/55 | 4138×3300×3650 | 6400 | |

| 2PGC Roller Crusher | 2PGC450×500 | 100-200 | 25-100 | 20-55 | <11 | 2368×2206×916 | 3368 |

| 2PGC600×750 | 300-600 | 50-125 | 60-125 | 22 | 2635×2850×1025 | 6612 | |

| 2PGC900×900 | <800 | 75-150 | 100-180 | 30 | 3710×2300×1394 | 13670 | |

| 2PGC1000×800 | 150-400 | 5-150 | 30-150 | 55 | 3480×2300×1360 | 10715 | |

| 2PGC1200×1500 | <200 | <40 | 100-160 | 2×55 | 3370×3500×1945 | 26000 | |

| 2PGC1200×1500 | <150 | <20 | 450-600 | 250×2 | 5890×4220×2370 | 58162 |

Hydraulic roller crusher introduction

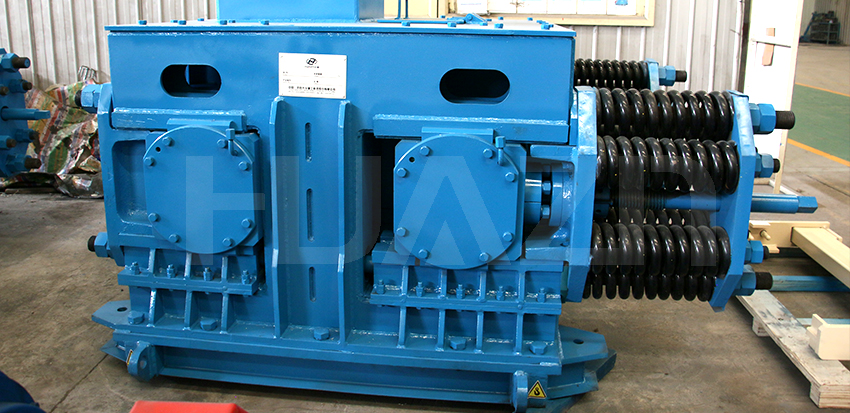

The large hydraulic roller crusher incorporates mechanical, electrical, and hydraulic designs to ensure uninterrupted stability and dependable operation. The sand aggregate and grinding system can be effectively enhanced by 30%-40% in terms of output, while simultaneously reducing total energy consumption by 20%-30%. The equipment stands out in terms of performance due to its well-structured design and comprehensive range of functions.

Working principle: The operational principle involves a set of parallel and horizontally positioned cylindrical rollers. The material is fed into the feeding port and subsequently falls onto the roller surface as the rollers rotate in opposite directions. The material is fragmented into small pieces through the combined action of various forces, which surpasses the binding force within the lattice structure and achieves the purpose of crushing. Subsequently, the crushed material is discharged downwards by the rotating roller.

What are the features of hydraulic roller crusher?

1、The equipment is equipped with an automated control system, ensuring seamless operation and optimal efficiency. In comparison to other crushing systems of equivalent performance, it effectively minimizes costs.

2、The roller gap can be adjusted hydraulically to maintain stable operation within the range of 1-40 mm.

3、The rollers are equipped with overload protection, enabling them to automatically detect and avoid any non-breakable material that enters between them, while also restoring themselves to the predetermined clearance.

4、The utilization of heavy-duty thickening rollers, meticulous material selection, exceptional wear and impact resistance, combined with an automatic lubrication device, significantly enhances the longevity of components.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher. From machine selection to site installation, and operator training, the professional engineer will take in charge of the whole process. Please contact us at any time to get latest quotation.