In the crushing industry, there are many crushers that can be used, among which the most commonly used are impact crusher and hammer crusher. These two crushers have their own benefits, and many customers want to know the difference between them. Today, Luoyang Dahua crusher manufacturer will talk about the specific difference between impact crusher and hammer crusher.

The scope of application:

Impact crusher is suitable for handling the materials with the side length below 100-500 mm, which is widely used in building materials, ore crushing, highway, energy, transportation, cement, mining, chemical and other industries.

Hammer crusher is suitable for crushing the rocks with compressive strength not more than 150 mpa. It can be used in crushing production line, sand making production line, and also in mineral processing production line instead of cone crusher.

Different grain shapes:

Impact crusher: The finished product of the impact crusher has a good grain shape. The discharging material is cubic with a uniform particle size as well as low fine powder and dust.

Hammer crusher: The hammer crusher has a relatively large reduction ratio, generally 10-25, even 50. However, its finished products contain more needles and flake materials and powder.

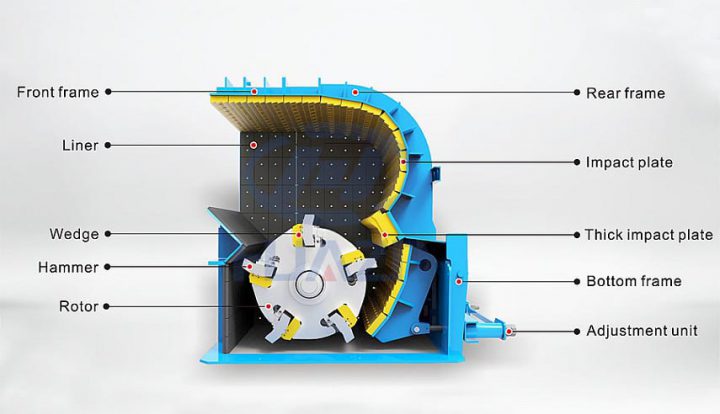

Structural differences:

Impact crusher is mainly composed of plate hammer, compression block, impact plate and square steel, etc. The impact plate mainly bears the impacting of the material hit back by the plate hammer, so that the material is broken again by impacting force, and the material will bounce back to the impact zone.

Hammer crusher is mainly composed of shell, rotor, hammer head, impact lining plate, sieve plate and so on. The hammer head of hammer crusher is the main working part, which is responsible for crushing the material. It adopts new high-quality multi-element high-chromium manganese steel composite casting, and its service life is several times than that of the general hammer head.

The wear of vulnerable parts of the impact crusher is smaller than that of the hammer crusher, and the metal utilization rate is high. The replacement of spare parts of the impact crusher is simple and the maintenance cost is reduced accordingly.

Luoyang Dahua has more than 30 years experience in manufacturing various kinds of stone crusher, jaw crusher, cone crusher, and EPC solution for the customers. If you don’t know how to choose crusher machine, please contact us at any time. Whatsapp: +86 13938852499