Linear vibrating screen take advantage of double vibration motor as excitation sources. It is used for screening and grading of powdery and granular materials. Linear vibrating screen is widely used in coal, hydropower, mining, building materials, chemical and other industries, which has the feature of low consumption, and high output.

The advantages of linear vibrating screen:

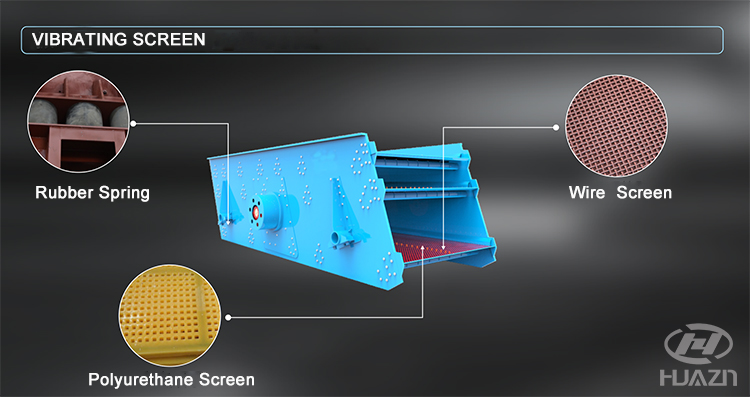

1. Unique sieve design, convenient and fast to replace(3- 5 minutes). In addition, this special design allows various kinds of sieve (nylon, PP sieve) to be used.

2. Screen machine is easy to assemble with smart design, and easy for operation.

3. Wide screening area, high processing capacity.

4. Fine sieve is supported by the basic sieve which has longer service life. So reduce the usage of fine sieve, prolong service life can decrease the operation cost.

The development trend of vibrating screen:

1. High efficiency and large output. With the development of industry, manage field of enterprise become larger, production ability of sand making machine has been greatly improved, and work together with screen machine.

2. More standardization, serialization and universalization. It is the way to keep quality and reduce cost.

3. Large vibrating strength. Improve the technical data of vibrating screen to get higher speed and accelerated speed.

4. Light weight, environment friendly, simple distribution. The old vibrating screen is complex to change screen. There are 48 bolts to fasten screen, normally it takes 4 hours to change a new one. With the requirement of industry department for vibrating screen, the new screen should be reformed in light weight, environment friendly and simple distribution.

In the future, the vibrating screen will keep booming promoted by the development of coal, iron mineral, nonferrous mineral, chemical industry, cement and etc.

The linear vibrating screen manufactured by Luoyang Dahua is widely applied in coal, hydroelectricity, mining with the maximum feed size of 250mm. If you are interested in it, please contact us.