The different sand and stone aggregate are processed to different fineness to supply to each building project. Different stone materials and different discharge particle size have different configuration schemes. The configuration scheme of the gravel production line with the discharge of 10-20mm, 20-30mm and 0-5mm stone is as follows:

The discharge of 10-20mm, 20-30mm stone production line configuration

The specification of this type of gravel can solve the shortage of building stone. If you want to produce these particle sizes, the equipment configuration of gravel production line is also different.

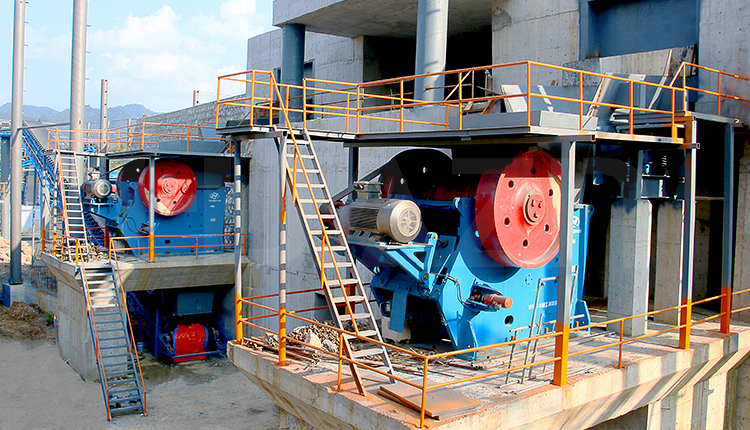

Required equipment: jaw crusher + cone crusher (impact crusher)+ vibrating feeder + vibrating screen + belt conveyor; Cone crusher is used for fine processing of high hardness stone into 10-20, 20-30mm stone, impact crusher is used for fine processing of medium hardness stone. After that, qualified stones are selected through the vibrating screen.

The discharge of 0-5mm stone production line configuration

0-5mm sand is the mechanical sand on the market that can be used in construction and production. The mechanical sand has the advantages of diverse grain size and good grain shape. In order to produce 0-5mm stone, the equipment configuration required by the production line is as follows.

Required equipment: jaw crusher + cone crusher (impact crusher)+ sand making machine + vibrating screen + vibrating feeder; When dealing with different hardness of stone, the proper curser machine should be selected. The gravel is processed into 0-5mm by a sand making machine, and then the unqualified machine-made sand is broken again by a screen machine, and the qualified machine-made sand is returned to the finished product area.

Luoyang Dahua has 60+ years experience in manufacturing mining crusher machine, the hot products are jaw crusher, cone crusher, impact crusher, sand making machine, and mobile crusher station. If you want to know more, please contact us at any time.